HJT Series Solar Panel

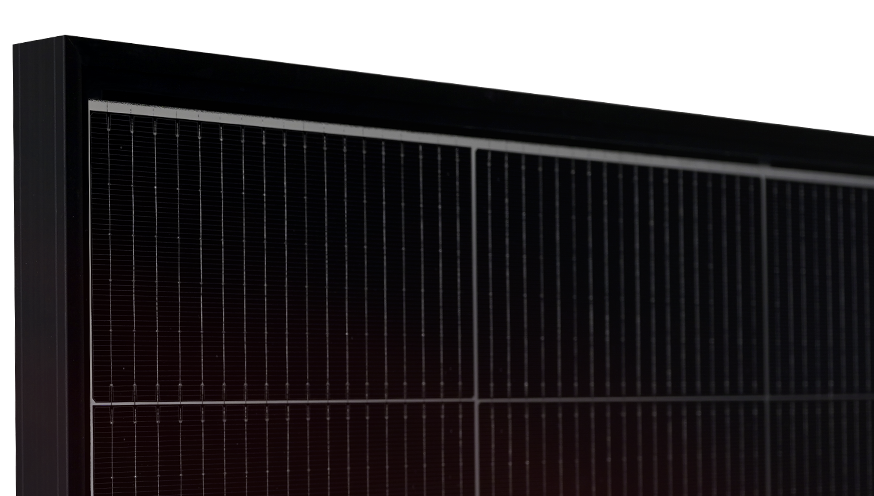

Maysun Solar 410W-430W HJT Solar Panel Full Black Glass Glass Bifacial

Power Output: 410W 415W 420W 425W 430W

Efficiency: 21.2-22.3%

Dimensions (L × W × H): 1760 mm × 1098 mm × 30 mm

Weight: 22 kg

Packaging: 36 pcs/pallet, 936 pcs/40’HQ

Warranty: 30-year product and performance guarantee

Datasheet: Download

Maysun Solar HJT Solar Panel Full Black 410W-430W Bifacial Glass Glass Transparent

Power Output: 410W, 415W, 420W, 425W, 430W

Efficiency: 21.2% – 22.3%

Dimensions (L × W × H): 1760 mm × 1098 mm × 30 mm

Weight: 22 kg

Packaging: 36 pcs/pallet, 936 pcs/ 40’HQ

Warranty: 30-year product and performance warranty

Datasheet: Download

Maysun Solar 675W-710W HJT Solar Panel with Silver Frame Glass Glass Bifacial

Power: 675W 680W 685W 690W 695W 700W 705W 710W

Efficiency: 21.74%-22.87%

Dimensions (L × W × H): 2383mm × 1303mm × 35mm

Weight: 38.5 kg

Packaging: 31 pcs/pallet, 558 pcs/40’HQ

Warranty: 30-year product and performance warranty

Datasheet: Download

High-Efficiency Heterojunction Solar Panel

Heterojunction (HJT: Heterojunction Technology) seamlessly merges the strengths of crystalline silicon and amorphous silicon thin-film technologies, delivering superior light absorption and exceptional passivation capabilities. With higher efficiency and enhanced performance compared to PERC technology, HJT stands as a cutting-edge innovation in the solar industry, driving conversion rates and power output to new heights.

Application Scenarios for HJT Solar Panels

HJT technology boasts high bifaciality and a low-temperature coefficient, enhancing solar panel efficiency and power generation while reducing the cost per unit of electricity. This makes it an ideal choice for regions with hot summer climates, such as Southern Europe. Additionally, it is highly suitable for applications like agricultural photovoltaics, carport systems, and fence-mounted photovoltaics.

High-Efficiency Solar Panel

High conversion rate and high power output solar modules

High-Efficiency Solar Modules

Equipped with high-efficiency HJT 210mm solar cells, the TCO thin film effectively passivates interface defects in crystalline silicon and doped amorphous silicon, achieving a photovoltaic conversion efficiency of up to 25%.

High Bifaciality Solar Modules

HJT cells feature a symmetrical structure and an advanced conductive grid, delivering exceptional rear-side power generation efficiency exceeding 95%. This innovative design far surpasses traditional PERC and TopCon technologies, providing a remarkable 10% to 35% increase in rear-side power generation.

HJT |

TOPCON |

PERC |

|

Bifacial Yield |

95% | 85% | 70% |

Power Generation Efficiency |

22.87% | 22.28% | 21.20% |

Initial Power Degradation in the First Year |

1% | 1.5 | 2% |

Average Annual Power Degradation from the Second Year |

0.35% | 0.4% | 0.45% |

Temperature Coefficient |

-0.243%/°C | -0.32%/℃ | -0.35%/℃ |

Services by Maysun Solar

Maysun is dedicated to delivering premium-quality products and exceptional services to its customers.

30-Year Warranties

Extended product and performance warranties.

Europe-wide Dealer Network

Accessible solar energy solutions throughout Europe.

Sufficient Stock

Ensuring constant availability to meet your needs.

Over 15 Years of Experience in the PV Industry

Trusted by an extensive and reliable global customer base.

Fast Delivery with Reliable Customer Support

21 European warehouses ensure quick access to solar solutions.

Technical Team for Professional Products

Staying informed about the latest trends in Solar Energy technologies.

Comprehensive and Detailed Technical Manuals

Comprehensive professional technical support.

Certification by TÜV, CE, and Fire Safety

Recognized international professional certification.

Frequently Asked Questions

Since Waler Fuhs first proposed the HJT structure in 1974, combining amorphous silicon with crystalline silicon materials, the development of HJT cells has progressed steadily. In 1989, the Sanyo Group successfully developed HJT solar cells and filed a patent, achieving an efficiency of 15% at the time. By 1997, Sanyo registered the HJT trademark and began commercializing photovoltaic modules, marking a pivotal step in HJT’s early development.

After 2010, with Panasonic’s HJT patent expiration, other manufacturers started advancing this technology, pushing HJT solar panels into industrial production and continuously improving their conversion efficiency. In 2017, HJT solar panels officially entered the commercial phase, attracting more companies to join the industry and initiate small-scale production. With an increasing number of production lines exceeding 100 MW, the future of HJT technology appears highly promising.

In the HJT module, amorphous silicon is deposited onto an N-type silicon wafer substrate to create a heterojunction that acts as a passivation layer, enhancing open-circuit voltage and overall efficiency. The cell structure also includes an outer layer with a transparent conductive oxide (TCO) coating. The manufacturing process utilizes low-temperature techniques, with silver paste processing temperatures typically around 200°C. This enables the use of thinner N-type silicon wafers, presenting significant opportunities for future cost reductions.

In electronics, there’s a principle: fewer solder joints result in a lower failure rate. IBC cells eliminate solder joints on the front and utilize conductive adhesive on the back, reducing solder joints by over 80%. This design minimizes solder-related damages and significantly lowers the risk of poor soldering, enhancing reliability.

What Are Heterojunction Technology (HJT) Solar Panels: Advantages & Applications

November 29, 2023

The Bifaciality of Solar Panels: A Comprehensive Guide from Principles to Applications

October 28, 2024