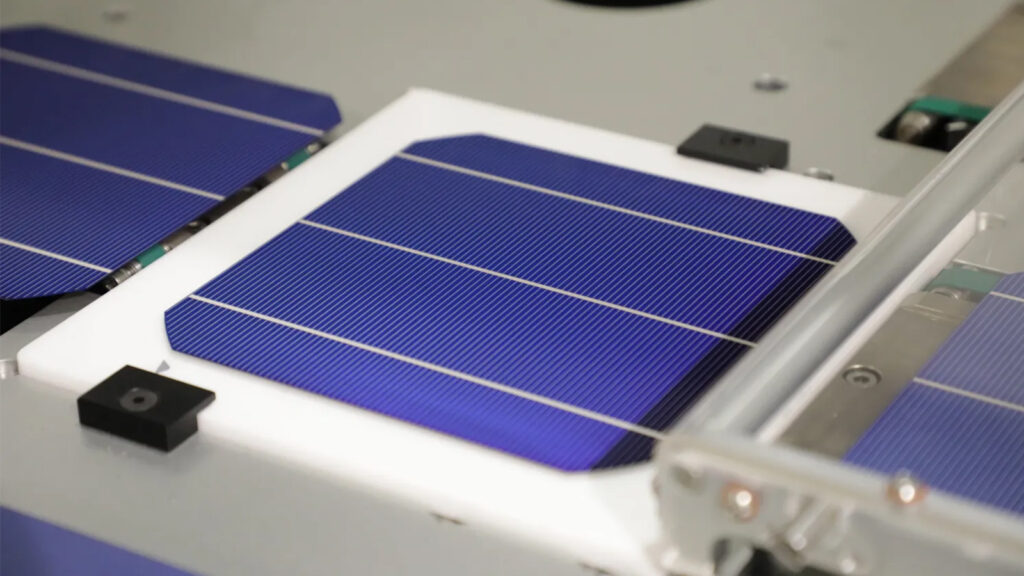

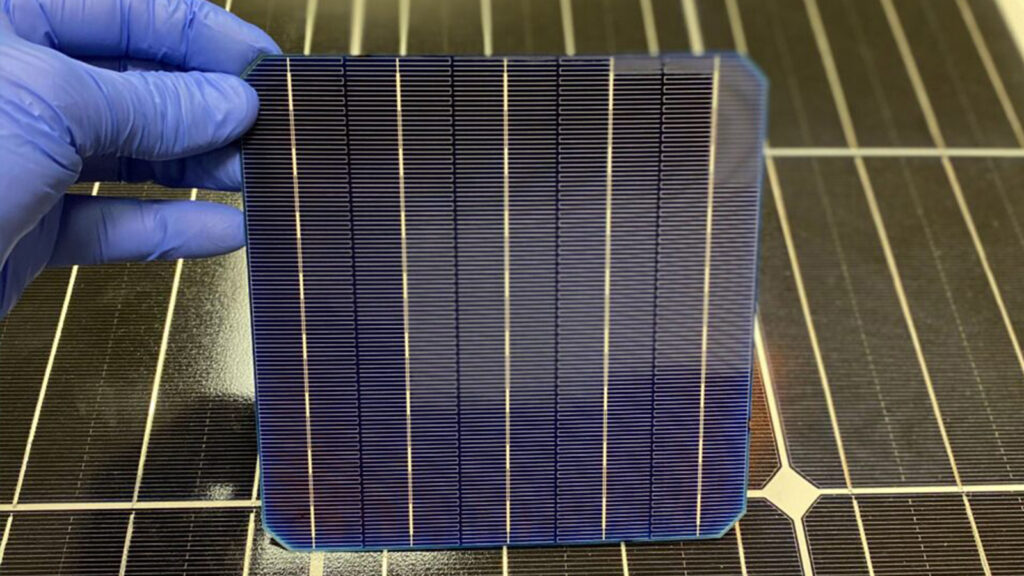

The most important part of a photovoltaic panel is a small cell welded by photovoltaic welding tape, which converts light energy into electricity. As the connection of the cell and the important role of receiving the current flow of photovoltaic welding tape, do you know about it? In this article, we will tell you some tips about photovoltaic welding tape.

What is photovoltaic tape?

Photovoltaic tape is a kind of tin-coated copper tape composed of metallic tin and metallic copper. It is a conductive lead tape for solar cells. It will carry the electrical energy converted from light energy on the cell to the electrical equipment, and it also has a certain heat dissipation effect affected by the current and voltage. Therefore, it is one of the important components of solar photovoltaic panels. The quality of photovoltaic welding tape is related to the power transmission efficiency and service life of photovoltaic modules. The appearance size, mechanical properties, surface structure, resistivity and other performance indicators of photovoltaic welding tape affect the efficiency of photovoltaic power generation. High-quality PV tape not only significantly improves the power generation efficiency, but also reduces the fragmentation rate of PV panels due to the high-quality connection capability.

The main materials of PV solder tapes are: copper base material, tin alloy coating and flux. The workers generally apply a continuous and uniform layer of melting point alloy on the surface of the copper tape of a set specification using a specialized method to create a photovoltaic tape that meets the requirements for use.

What types of photovoltaic tape are available?

The main types of photovoltaic tapes available on the market today can be divided into interconnection welding strip and busbar strip according to their application direction.

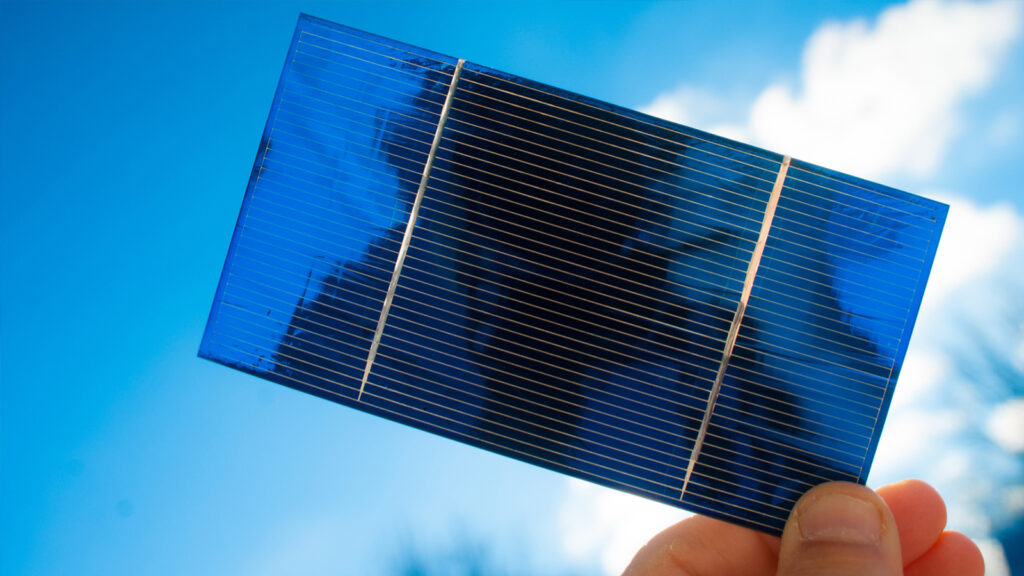

interconnection welding strip is a tinned solder tape used to connect PV cells and collect and transmit the current of PV cells. It is connected to the front grid line and the back grid line of the cell, connecting the positive and negative poles of adjacent cells, forming a series circuit to transmit the electrical energy from the cells to the electrical equipment. busbar strip connects the battery strings to the junction box to achieve a complete current circuit flow.

Obviously, the amount of consumables used for interconnection tape far exceeds that of sink tape.

Interconnection welding strips can be divided into:

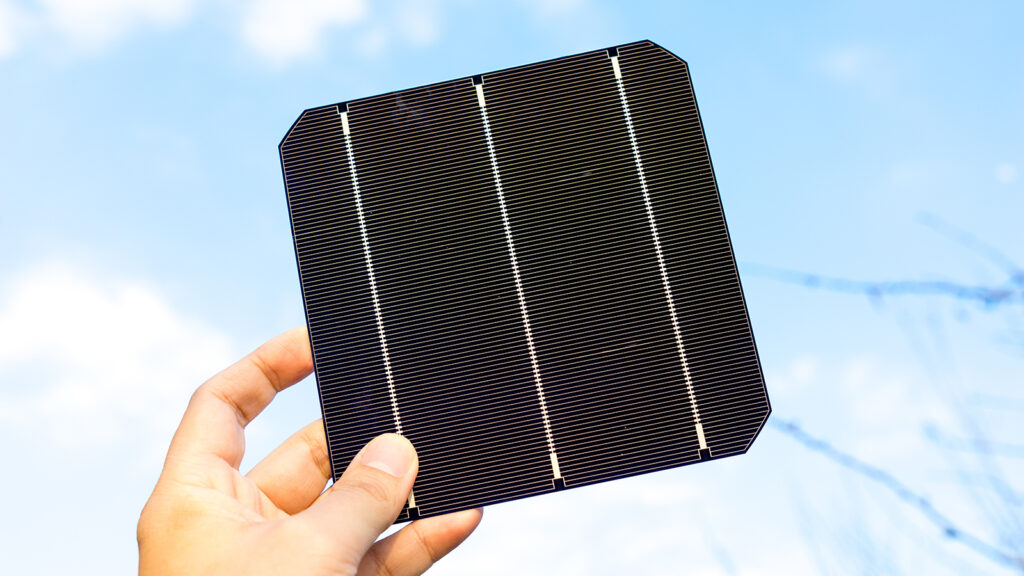

1. Conventional solder strips

Suitable for conventional components and meet the needs of conventional components.

2. MBB solder tape

Suitable for multi-gate modules, thinner than conventional tape, the more western the gate line, reducing the masking area of the tape on the cell and improving the utilization efficiency. At the same time, it makes the cell density distribution more even and the module power is obviously increased.

3. Low temperature welding tape

Suitable for HJT cell modules, it can achieve low temperature welding, which is conducive to reducing the shattering rate of PV cells.

There are other low resistance welding tapes and shaped welding tapes.

Busbar welding tapes can be divided into:

1. Stacked tile welding tape

Suitable for stacked tile modules, this type of tape is thin and low strength, high density of stacked tile modules, can be flipped to achieve a small version without increasing the rate of cell fragmentation, can be engaged in improving the power per unit area of the cell.

2. Stamped welding tape

It is applicable to the stacked tile module, and has an additional process based on the stacked tile welding tape. The purpose is to make hollow welding tape in the middle part for the connection of the stacked tile type cells.

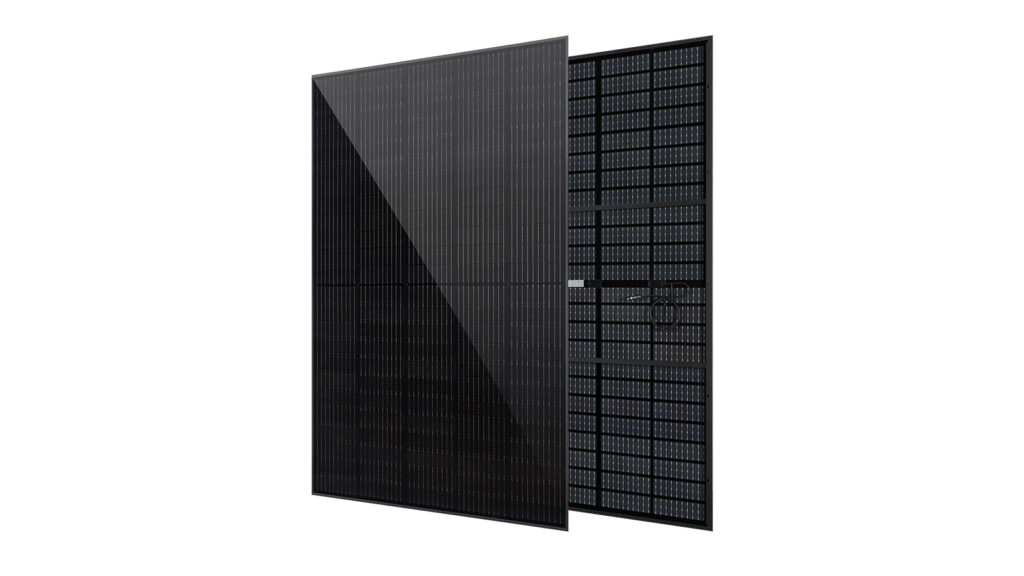

3. Black welding tape

It is suitable for all-black modules and is color-matched according to the module appearance requirements to keep the color of the welding tape consistent with the appearance of the module frame and cells, so as to achieve the purpose of aesthetics and reduce optical pollution.

Conventional and bending tapes are also available.

Maysun Solar, as a manufacturer with 15 years of experience in PV module production, offers different types of PV modules for purchase. Click on the button below to make an inquiry! You can also visit our website for more textual information.

You may also like:

Will Agrivoltaics Affect Crop Growth?

Agrivoltaics combines solar energy and agriculture to reduce up to 700 tons of CO₂ per MW, improve water use, and boost crop growth for sustainable farming.

6.5 Billion Loss Hits Photovoltaics: Reshaping or Elimination?

In 2025, the photovoltaic market may see a turnaround as some companies take early action. A €6.5 billion loss is driving businesses to explore new growth areas like energy storage and hydrogen. Which giants will break through? Industry transformation is accelerating!

What’s New in Solar Energy (March 2025)

March’s solar news highlights include rooftop solar meeting two-thirds of global demand, China’s market reforms potentially boosting solar demand and module prices, France revising solar targets in PPE 3, and challenges in Europe with declining capture rates and price volatility.

Zero-Investment Solar Projects: How to Earn Passive Income Through Rooftop Leasing?

Monetize your idle rooftop and earn stable annual rent! With the photovoltaic rooftop leasing model, businesses can generate long-term revenue without investment, reduce operating costs, and achieve a green transition.

How to Optimize Photovoltaic Power Plant Operations with AI and Big Data

This article explores three methods of using AI to enhance power generation revenue and reduce operation and maintenance costs in intelligent photovoltaic operations.

Solar Module Costs May Rise by 10% in 2026! In-Depth Analysis of CBAM’s Impact on the Industry

Table of Contents Introduction to CBAM 1. Why Did the EU Introduce CBAM? As the challenges posed by global climate change intensify, governments worldwide are accelerating their efforts to achieve carbon neutrality. The European Union, a leader in global carbon reduction initiatives, introduced