Today, PV giant Longi released its latest product, which attracted a lot of attention. At the same time, the HPBC photovoltaic cell technology adopted by the new product has become a hot topic in the photovoltaic field. So what is HPBC? Will HPBC become a mainstream technology for the next generation of photovoltaic cells?

HPBC, the full name is Hybrid Passivated Back contact Cell, is the product of IBC technology superimposed on P-type cell. To understand HPBC, you must first understand IBC technology.

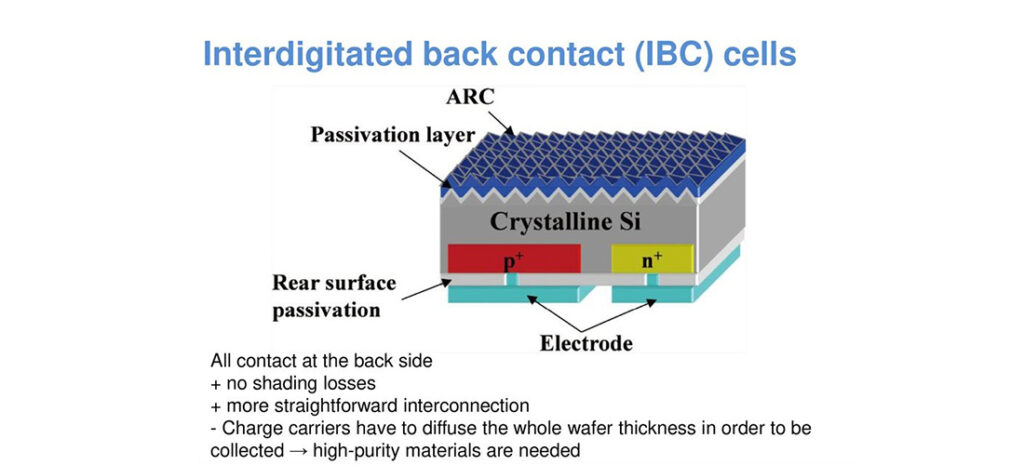

IBC

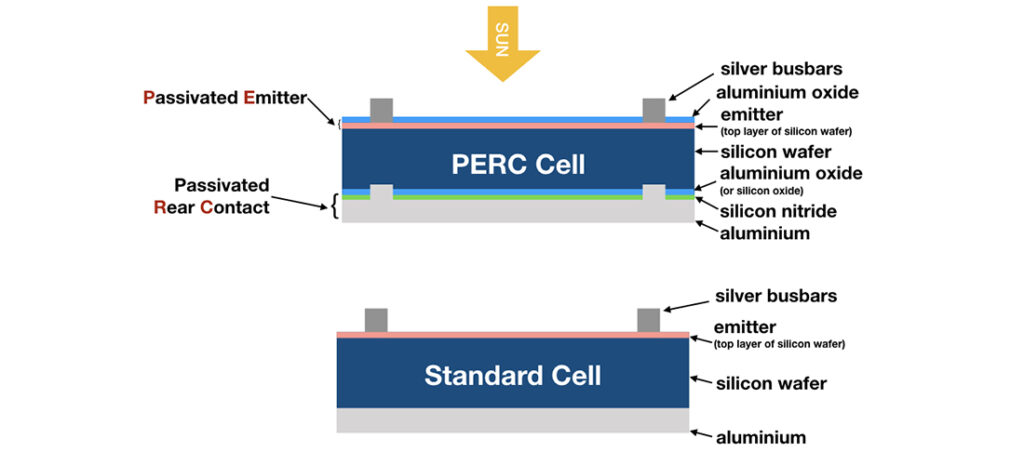

IBC (Interdigitated Back Contact) applies to a structure with no electrodes on the front of a cell and with positive and negative metal grid wires crossed on the back of the cell. The core technology of IBC lies in how to prepare the p and n regions with good quality and interlaced fingers on the back of the cell.

IBC technology was first proposed by Lammert and Schwartz in 1975. Sunpower is the leader and pioneer of IBC batteries. In March 2017, the Japanese company Kaneka obtained an HBC cell by superimposing HJT and IBC cell technologies, with an efficiency of 26.7%. This efficiency record has been maintained for 5 years.

Advantage of IBC

The special structure design of IBC cell makes it have the following advantages:

1) There is no grid line on the front of the cell, which can eliminate the shielding current loss of the metal electrode and realize the maximum utilization of the incident photon. Compared with the conventional solar cell, the short-circuit current can be increased by about 7%;

2) Both positive and negative electrodes are on the back of the cell, so it is unnecessary to consider the grid line occlusion problem, and the grid line proportion can be properly widened, so as to reduce the series resistance;

3) Since grid line shading, metal contact and other factors are not taken into account on the front side, surface passivation and surface light trapping structure can be optimized to obtain lower front surface recombination rate and surface reflection, so as to improve Voc and Jsc;

4) Beautiful appearance, especially suitable for light-volt building integration, with good commercial prospects;

Challenges for IBC:

Higher requirements for matrix materials; IBC cells require higher passivation of the front surface. The process of IBC is complicated, and the manufacturing cost of IBC is much higher than that of traditional crystalline silicon cells.

It is because of these challenges that the commercialization of IBC cells is full of obstacles.

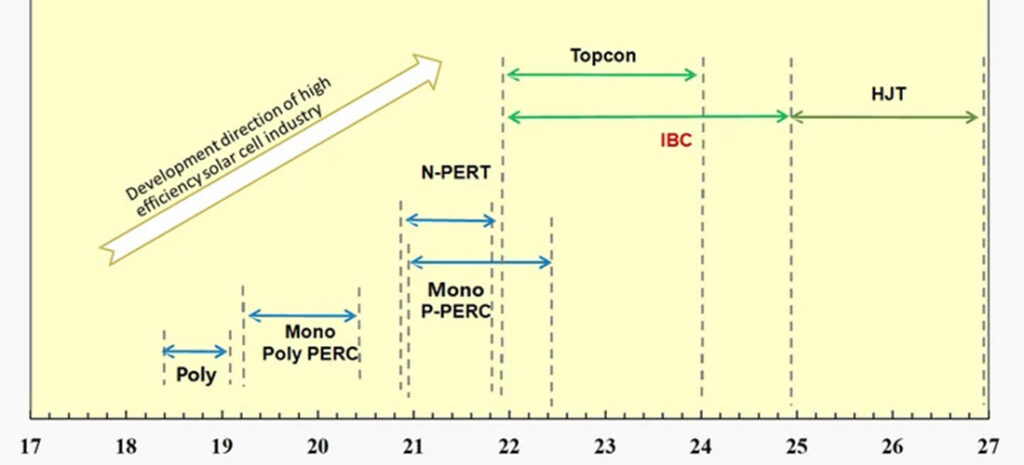

At present, IBC cell technology is mostly applied to N-type silicon wafers in the market. Compared with P-type cell modules, N-type cell modules have the advantages of low attenuation, high lifetime of few particles, good low light effect, and low temperature coefficient. N-type cell modules have the advantages of higher power generation under the same installed capacity, and N-type modules have reasonable premium and will exist for a long time. As a new cell technology platform, IBC can be stacked with HJT, TOPCon, PERC and other cell technologies, which has a huge space for future development.

HPBC

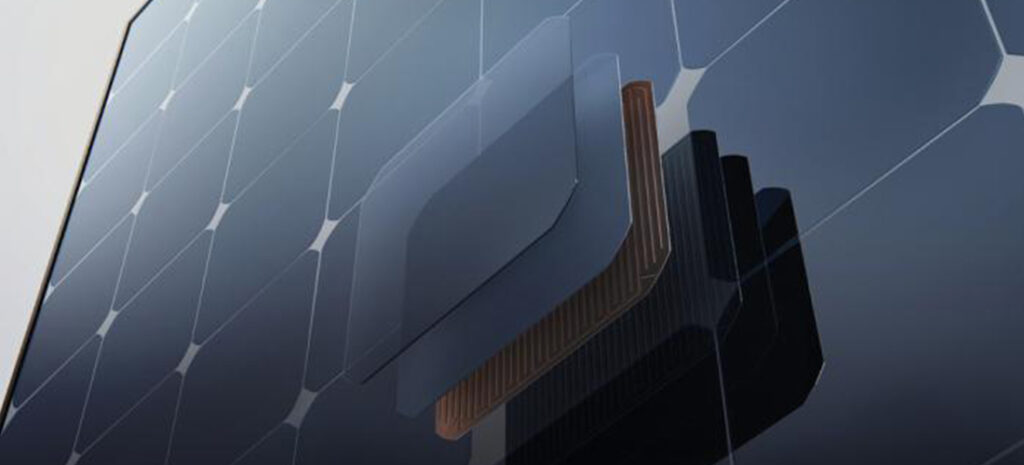

This time, Longi chose to use IBC technology on P-type silicon chips, which is the first in the industry. HPBC technology can achieve a cell efficiency of 25%. The power of the 72-type bifacial module is 575W, and the corresponding module efficiency is 22.3%. Compared with the mainstream PERC module, the power is 25W higher and the efficiency is 1% higher.Thanks to HPBC’s advanced cell technology and the new connection technology, the module can achieve lower linear attenuation. The attenuation and linear attenuation in the first year are reduced to 1.5% and 0.4%/year respectively, which is a big improvement compared to mainstream PERC modules.With the high conversion efficiency and open circuit voltage of the module, the power temperature coefficient of the HPBC module is better, which will further improve the power generation of the module. Due to lower attenuation and better temperature coefficient, the comprehensive power generation capacity of LONGi HPBC modules is about 3% higher than that of mainstream PERC modules. In addition, the design of no metal grid lines on the front of the HPBC cell makes the HPBC modules have a higher appearance, especially in the scenarios where customers have higher requirements on the appearance of distributed power plants such as households, which can better meet the needs of customers.

As HPBC gradually attracts attention, HPBC, TOPCon, and HJT will compete for the next-generation mainstream technology. But at the current time when the N-type is rampant, can HPBC find another way to become a dark horse? It remains to be verified by time. Some people in the industry also believe that, at present, HPBC has a small improvement in efficiency, and more is a small improvement, and its cost is slightly higher, and the economy remains to be seen.

Maysun Solar has always been an active practitioner of the most advanced technologies in the photovoltaic industry. For this new technology, we will also continue to pay attention to it, you can contact us for the latest company news