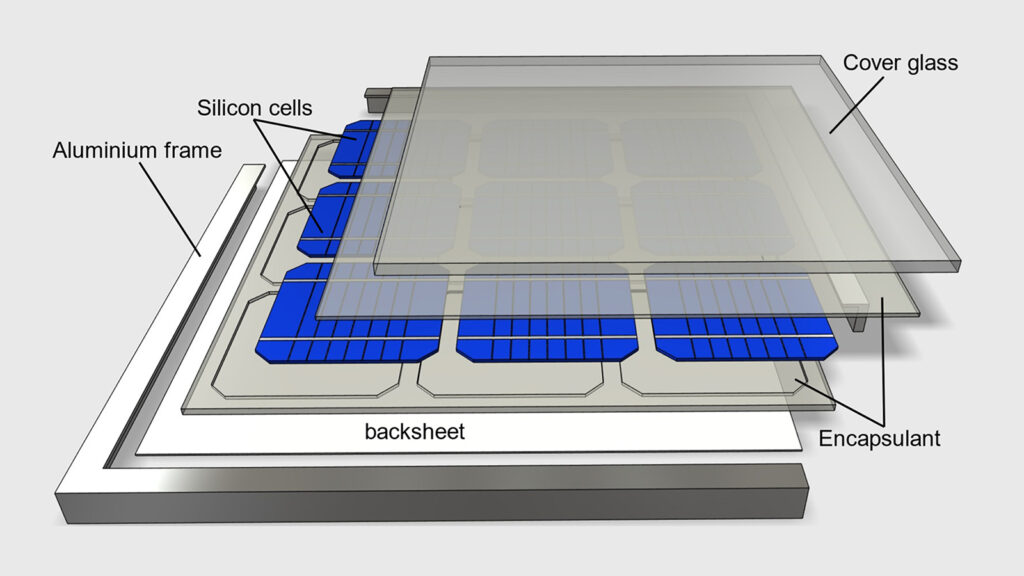

The long-term stability of photovoltaic modules is key to the continuous production of electricity from a photovoltaic system. As an important part of the PV panel, the backside protects the cells, but there are some common problems during production and later use. Below is a list of common problems with PV backplates that Maysun Solar has compiled for you.

1. Yellowing

When laminating solar modules, two layers of adhesive film are used to bond the solar cells to the glass and backsheet as a unit. One of the two layers of adhesive film is generally required to block short-wave UV light. The backsheet itself is resistant to UV light at 300nm-380nm, but a portion of the backsheet still yellows under UV light, leading to the destruction of molecular components in the backsheet layer and a reduction in the overall performance of the backsheet layer, as well as a reduction in the reflectivity of the backsheet layer, which affects the overall power output of the module.

Fluorinated materials are inherently UV-resistant unless otherwise treated. If both layers of the film do not shield short-wave UV light, the UV light will directly cause yellowing of the backsheet on the lower layer. The yellowing of the backsheet reduces the reflection of sunlight, which in turn affects the absorption of sunlight by the solar cell and ultimately reduces the power output of the module.

2. Bulging

The location of the hot spot on the cell and the location of the invisible tape are both prone to bubbling out of the baking sheet, especially when the two locations overlap, which is mainly caused by high temperatures leading to material vaporization.

The UV absorber in EVA converts the absorbed UV light into part of the heat energy and emits it to the module.

Generally speaking, the maximum working temperature of a normal module is between 70 °C and 80 °C. According to the test data, the increase in temperature will affect the output power of the module, and for every 1 °C increase in the temperature of the module, the output power of the module will be reduced by about 1 W. Therefore, the heat transfer coefficient of the backsheet material should be considered during the selection process.

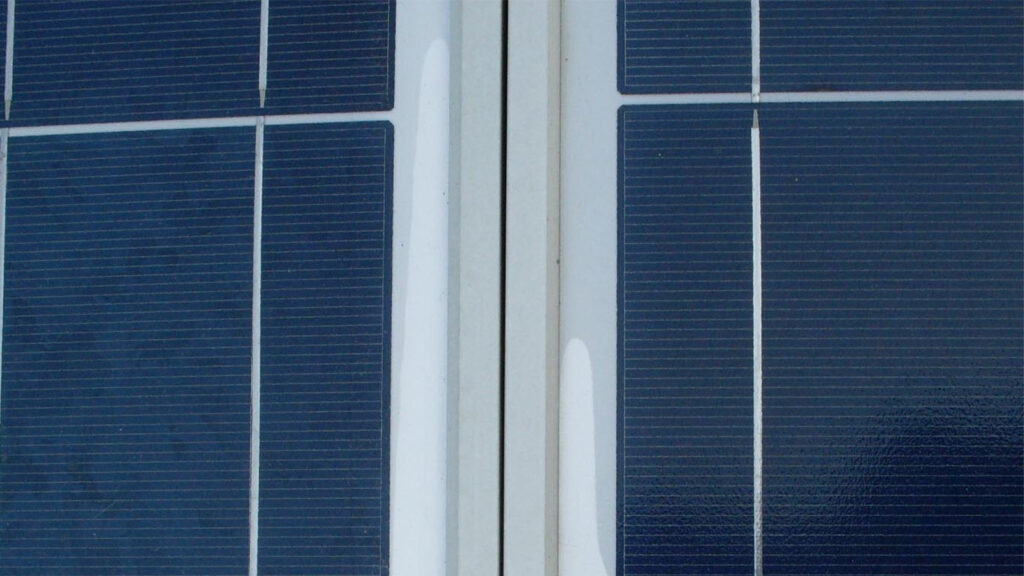

3. Air bubbles

The backsheet strips cause a large gradient between the converging strips, and the laying personnel do not put the EVA strips in place, so the EVA is not filled well. In the later use of the components, the bubbles will gradually expand and the material around the bubbles will oxidize and deteriorate, which greatly affects the service life of the components.

4. Report

Scratches can occur in several different ways: 1. from the raw material itself, 2. from sharp objects that cause scratches on the back during transportation on the transmission line, 3. from damage caused by trimmers in the trimming process.

The main roles of the backing plate in the assembly are moisture, dust and insulation. Scratches on the backplate greatly reduce the moisture resistance of the component, which will accelerate the oxidation of the component, and the anti-insulating properties will reduce the safety performance of the component. Scratches also increase the water permeability of the backside, and excessive water vapor entering the module directly leads to corrosion of the internal circuits, causing the module to lose its power generation performance over time, and the internal circuits are also destroyed due to severe oxidation, which means that the service life of the module will end.

If your photovoltaic backsheet exhibits any of these problems, you should contact the brand company you purchased it from as soon as possible. In addition to backsheet problems that can cause loss of solar power, there are many other common problems that can prevent a PV system from producing electricity, which you can see by clicking the button below.

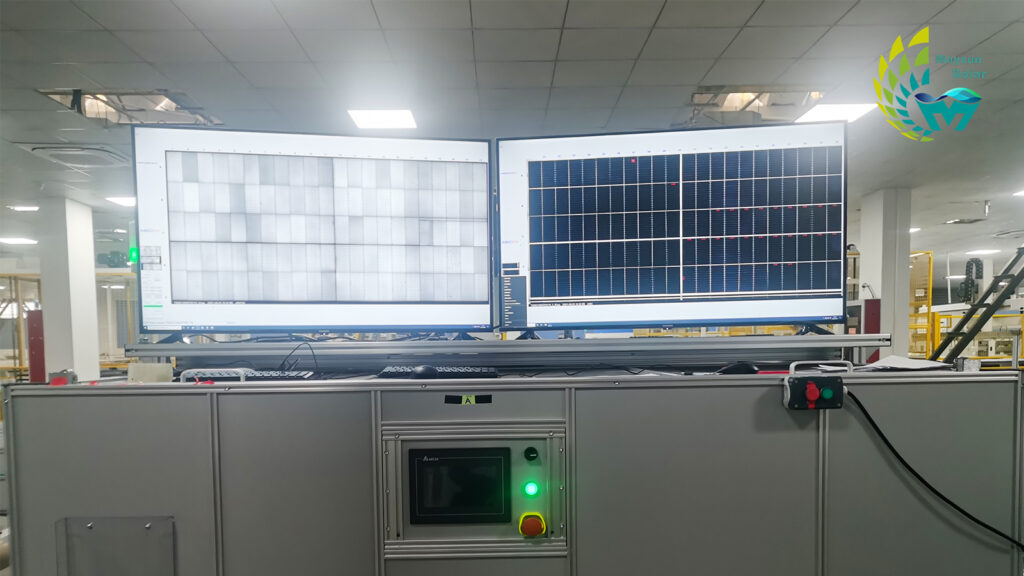

Maysun Solar, as a manufacturer of photovoltaic modules with 15 years of professional experience, performs a variety of tests during the manufacturing process and can provide you with high quality solar panels, click the button below to contact us to get a product quote.