Content:

Introduction

Series vs. Parallel Connections: A Comparison

Pros and Cons of Series vs. Parallel Connections

Solar Panels in Series or Parallel: Which is Best for Your Setup?

Common Issues and System Optimization in Series and Parallel Connections

Conclusion

Introduction

You want your solar panels to deliver the maximum amount of energy possible, right? But did you know that how your solar panels are connected within your system can make a big difference in their performance? Whether your panels are wired in series or parallel affects the current flow, voltage, and overall efficiency of your solar setup. The right configuration depends on factors like your system’s size, location, and energy needs. In this article, we’ll explore the key differences between series and parallel wiring, helping you decide which setup will maximize your energy output and optimize your solar investment.

Series vs. Parallel Connections: A Comparison

When setting up a solar power system, understanding the differences between series and parallel connections is crucial. These two configurations impact how voltage and current behave within the system.

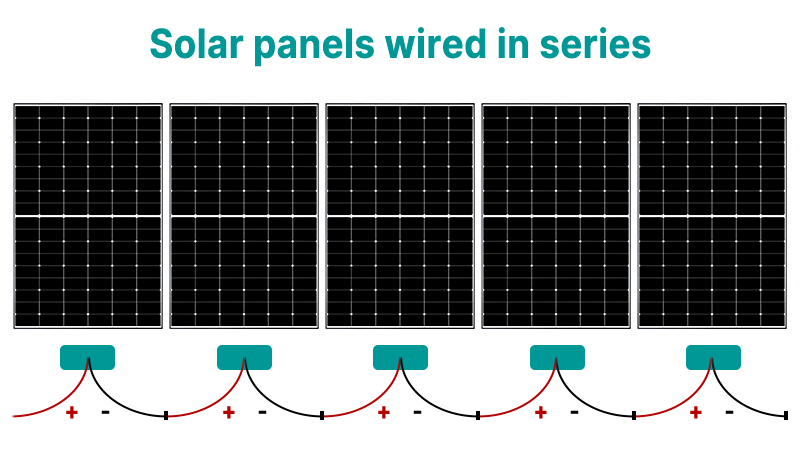

Series Connections

In a series connection, solar panels are linked end-to-end, where the positive terminal of one panel connects to the negative terminal of the next. This type of setup leads to an increase in the voltage but keeps the current the same as that of a single panel.

- Voltage and Current Behavior: The voltages from each panel add up, while the current remains constant.

- Example: If each panel generates 20V and 5A, three panels connected in series will output 60V and 5A.

Series connections are ideal when higher voltage is needed, such as in systems that use string inverters. Additionally, they are efficient for long-distance transmission because the increased voltage reduces energy losses from high current.

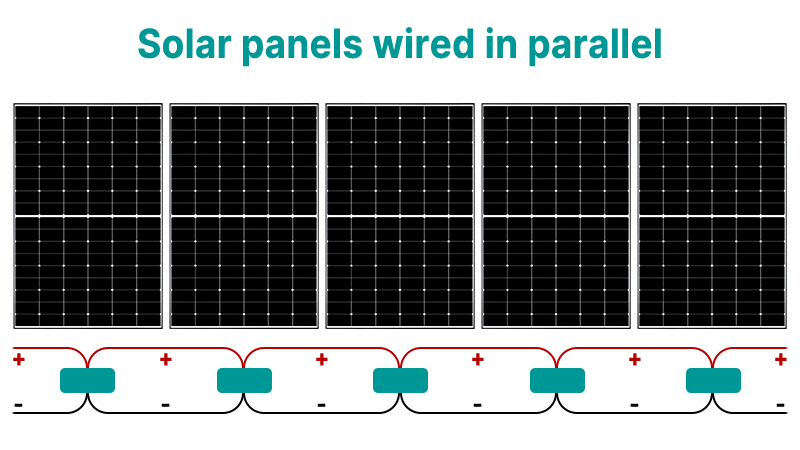

Parallel Connections

In a parallel connection, all the positive terminals of the panels are joined together, and all the negative terminals are also connected together. This arrangement keeps the voltage constant (as per a sing

Voltage and Current Behavior: Thle panel) while the current increases as more panels are added.

- e voltage stays the same as a single panel, but the current adds up.

- Example: With each panel providing 20V and 5A, three panels in parallel will result in 20V and 15A.

Parallel connections are ideal for applications requiring more current, like systems using MPPT (Maximum Power Point Tracking) charge controllers, or for storage systems like batteries where a higher current is needed for faster charging.

Pros and Cons of Series vs. Parallel Connections

Pros of Series Connections

- Higher Voltage: Series connections are ideal for systems that need higher voltage, such as on-grid installations. They are the best option when the system requires more voltage rather than higher current.

- Better Efficiency: Series connections tend to have better efficiency, as less power is lost over long distances. Voltage is transmitted more effectively than current.

- Thinner Cables: Because the current is lower in series configurations, the wiring can be thinner and cheaper compared to parallel connections.

- Suitable for Long Distances: Voltage transmission is more efficient over long distances, making series connections better for installations with extended cable runs.

Cons of Series Connections

- Shade Sensitivity: The output of the entire array depends on the performance of each panel. If one panel is shaded or damaged, it can reduce the overall output. In areas with frequent shading, parallel or hybrid connections might be better.

- Higher Voltage Risk: Series connections increase system voltage, which can be dangerous if not handled properly. Professional installation is recommended for high-voltage systems.

Pros of Parallel Connections

- Increased Current: Parallel connections add the current of each panel, which can be useful for systems that need higher current without increasing voltage.

- Less Impact from Shade: In parallel setups, shading on one panel only reduces that panel’s output, leaving the rest of the system unaffected. This makes parallel connections more resilient to shading.

- Constant Voltage: Parallel connections maintain the same voltage regardless of the number of panels added. This is useful for low-voltage systems and ensures the inverter isn’t overloaded.

- Expandable: Adding more panels in parallel doesn’t risk exceeding the inverter’s voltage capacity, making system expansion easier.

Cons of Parallel Connections

- Lower Efficiency: Parallel systems can be less efficient, especially in larger installations, due to higher current and greater power losses over long distances.

- Heat Sensitivity: Parallel connections are more affected by heat. As current increases, the system becomes more sensitive to temperature-induced performance drops.

- Thicker Cables: Parallel wiring requires thicker cables to handle higher current, which increases system cost and energy loss over long cable runs.

Solar Panels in Series or Parallel: Which is Best for Your Setup?

Use Series if your system requires higher voltage, has minimal shading, and involves long cable runs.

- Example:

Ina residential grid-tied system with 8 MaysunSolar panels rated at 20V and 5A each, you want to connect them in series to match your inverter’s required voltage of 160V. If you are using a PWM charge controller, the voltage needs to match the battery voltage (e.g., 12V, 24V, or 48V). However, using a MPPT charge controller is more efficient, as it adjusts the voltage to extract maximum power from the panels, even if the battery voltage differs from the panel output.- Series Setup:

- 8 panels x 20V = 160V(current remains 5A).

- If there is minimal shading and the distance between the panels and inverter is long, a series connection minimizes power loss from cable resistance.

- A MPPT charge controllerwould adjust the input from 160V to the optimal charging voltage for your battery, maximizing energy capture and efficiency.

- This setup works well for high-voltage systemsconnected to grid inverters or systems requiring higher vol

- Series Setup:

Use Parallel if your system is in a shaded area, requires lower voltage, or needs flexibility for future expansion.

- Example:

In a battery storage systemwith 4 MaysunSolar panels rated at 20V and 5A each, and located on a shaded rooftop, you decide to wire them in parallel to maintain the system’s required voltage of 20V.- Parallel Setup:

- Voltage remains 20V, while current adds up (5A + 5A + 5A + 5A = 20A).

- This setup allows you to take advantage of the sunlight available to each individual panel, even if one or two panels are partially shaded.

- If using a PWM charge controller, it will regulate the charging based on the system’s voltage (e.g., 12V or 24V battery) and will be less efficient than an MPPT charge controller, which can adapt to the higher voltage of the solar array and extract more power from the panels, ensuring more effective charging.

- A parallel connection is ideal for low-voltage battery systems where you need consistent 12V or 24V outputs.

- Parallel Setup:

Use Series-Parallel Hybrid if your system needs a balance of voltage and current and your installation has areas of both sunlight and shade.

- Example:

In a commercial solar power plant with 12 MaysunSolar panels rated at 20V and 5A each, located on a roof with some shaded areas, you opt for a hybrid connection.- Series Setup (for half the panels):

- 6 panels x 20V = 120V(current remains 5A).

- Parallel Setup (for the other half):

- 6 panels x 20V = 120V(current adds up: 5A + 5A + 5A + 5A + 5A + 5A = 30A).

- Hybrid Setup Outcome:

- The system ensures higher voltage for efficient power transmission, while the parallel connection ensures that shaded panels do not drag down the output of the entire system.

- If you are using a MPPT charge controller, it will efficiently adjust the voltage from the panels to the optimal level for charging the battery, ensuring maximum energy harvesting from both the series and parallel connections.

- This type of setup is ideal for large-scale installations with a mix of shading and sunlight, allowing for both voltage and current flexibility.

- Series Setup (for half the panels):

By evaluating your system’s needs (voltage, shading, and distance), and considering the type of PWM or MPPT charge controller you plan to use, you can choose the most suitable configuration for optimal performance. Always consult with a professional installer to ensure the best setup for your solar energy system!

Common Issues and System Optimization in Series and Parallel Connections

In photovoltaic (PV) systems, the choice between series and parallel connections affects system performance, maintenance, cost, safety, and installation quality. Understanding these common issues, combined with maintenance, fault analysis, system cost, safety, and installation recommendations, helps optimize system operation and enhance reliability. Below, we discuss key issues and solutions in these areas.

1. Maintenance and Fault Analysis

Series Connection:

In a series connection, the voltage of each solar panel adds up, while the current remains unchanged. The primary advantage of series connections is the voltage boost, making it suitable for long-distance transmission. However, the system is highly sensitive to individual module failures. Any failure (e.g., shading, aging, or damage) in one module directly impacts the entire system’s performance. Therefore, regular voltage output checks for each panel are crucial during maintenance. Common issues include:

- Inconsistent module voltage:When one module’s voltage drops, the efficiency of the entire series circuit decreases.

- Loose or damaged connections:Loose terminal connections or cables can cause unstable current flow or short circuits, compromising system stability.

- Module surface contamination:Dirt or snow accumulation on the module surface reduces light transmission and lowers power output.

Parallel Connection:

In a parallel connection, the current of each module adds up while the voltage remains the same. The advantage of parallel connections lies in module independence, where the failure of one module does not affect the operation of others, providing higher redundancy. However, excessive numbers of panels in parallel may overload the system’s current, leading to overheating or equipment damage. Common issues in parallel connections include:

- Current overload:When too many panels are connected in parallel, the current load may exceed the system’s design capacity, potentially damaging electrical components.

- Loose or shorted connections:Excessive current may lead to wear and loosening of connection wires, resulting in electrical faults that disrupt the system’s stability.

- Single module failure:Although a single module failure does not stop the entire system, it still causes some power loss.

2. System Cost Analysis

Series Connection:

Series connections are generally more cost-effective in terms of initial investment, as the electrical wiring is simpler. The cost of cables and connectors ranges from €250 to €350 per kilowatt peak (kWp). The installation process is also relatively straightforward, with labor costs between €150 to €250 per kWp. Overall, the initial investment typically ranges between €2,000 and €3,000. Over the long term, maintenance costs are higher due to the system’s sensitivity to module failures, with annual maintenance costs ranging from €250 to €400. Module replacement costs are approximately €1,200 to €1,500, usually occurring every 10 to 12 years. While series connections offer lower initial investment, higher long-term maintenance requirements may lead to higher total costs.

Parallel Connection:

In comparison to series connections, parallel systems require higher initial investments due to the need for more cables, connectors, and inverters. The cost of cables and connectors ranges from €300 to €400 per kWp. A parallel system also requires higher-performance inverters and electrical protection devices, costing between €250 and €400 per kWp. Labor costs are relatively higher, approximately €200 to €300 per kWp. As a result, the initial investment typically ranges from €3,500 to €5,000. Parallel connections offer higher redundancy, leading to lower failure rates, and thus, lower annual maintenance costs, typically between €200 and €300. Module replacement costs are similar to those in series connections, ranging from €1,200 to €1,500, and replacements occur every 12 to 15 years. Although parallel connections have a higher initial investment, their stability and lower maintenance costs make them more economical over the long term.

3. Safety and Installation Recommendations

When choosing the connection method for solar panels, safety is paramount. Whether in series, parallel, or a hybrid configuration, proper installation and electrical design are critical for ensuring long-term stability and safe operation.

- Voltage management in series connections:Series connections increase the output voltage, requiring components such as inverters, circuit breakers, and cables to withstand high voltages, preventing potential safety hazards from overvoltage.

- Current management in parallel connections:Parallel connections increase current load, requiring cables that meet current-carrying specifications and overload protection devices to prevent overheating or fire hazards.

- Protection for hybrid series-parallel connections:Hybrid configurations introduce more complexity, necessitating a balance of voltage and current characteristics. Installing overvoltage, overcurrent protection devices, and a Battery Management System (BMS) can prevent faults from propagating and ensure system stability.

- Environmental and temperature impacts: Environmental factors such as high temperatures and humidity can affect module performance. Using materials with good heat dissipation and waterproof designs ensures the system operates safely under harsh weather conditions.

Conclusion

In summary, the choice between series and parallel wiring for your solar panels depends on several factors, including the specific needs of your system, its location, and your performance goals. Series wiring increases voltage and is ideal for systems with long-distance wiring or limited space, while parallel wiring boosts current and is more suitable for scenarios where consistent power output is a priority. Ultimately, the right configuration can significantly impact your solar energy efficiency and overall system performance. For the best results, it’s always a good idea to consult with a solar energy professional to determine the most suitable wiring setup for your unique needs and ensure optimal energy production.

Since 2008, Maysun Solar has been dedicated to producing high-quality photovoltaic modules. Our range of solar panels, including IBC, HJT and TOPCon panels, and balcony solar stations, are manufactured using advanced technology and offer excellent performance and guaranteed quality. Maysun Solar has successfully established offices and warehouses in many countries and built long-term partnerships with top installers! For the latest quotes on solar panels or any photovoltaic-related inquiries, please contact us. We are committed to serving you, and our products provide reliable assurance.

Reference:

Yasaswini. (2024, August 27). Should solar panels be connected in series or parallel? Solar Products Information. https://blog.solarclue.com/blog/should-solar-panels-be-connected-in-series-or-parallel/

Ecoflow. (2024, November 18). Connecting solar panels in series or in parallel: Which is better? EcoFlow UK Blog. https://blog.ecoflow.com/uk/wiring-solar-panels-parallel-vs-series/

Recommend Reading:

Empowering Factories with Solar Energy A Strategic Tool for Controlling Production Electricity Costs

Commercial and industrial solar is becoming a key solution for factories to reduce electricity costs and hedge against price fluctuations. This article systematically analyzes its deployment models, cost advantages, and sustainable value pathways.

How Businesses Can Offset Carbon Taxes with Solar Power

This article analyzes the latest carbon tax policies and photovoltaic deduction strategies, helping European businesses legally reduce taxes, increase profits through solar investment, and achieve a win-win situation for both economy and environment.

Forecast and Response: Seizing the Next Decade’s Growth Dividend in Europe’s Commercial and Industrial Photovoltaics Market

Maysun Solar analyzes the growth trends of commercial and industrial photovoltaics in Europe over the next ten years, from policies and ESG to technological innovation, helping companies seize the initiative in the energy transition.

How to Calculate Solar System ROI and Optimize Long-Term Returns?

Solar power is becoming a key solution for businesses to reduce costs and improve efficiency. Accurately calculating ROI and optimizing long-term returns are essential to maximizing investment value.

Will Agrivoltaics Affect Crop Growth?

Agrivoltaics combines solar energy and agriculture to reduce up to 700 tons of CO₂ per MW, improve water use, and boost crop growth for sustainable farming.

6.5 Billion Loss Hits Photovoltaics: Reshaping or Elimination?

In 2025, the photovoltaic market may see a turnaround as some companies take early action. A €6.5 billion loss is driving businesses to explore new growth areas like energy storage and hydrogen. Which giants will break through? Industry transformation is accelerating!