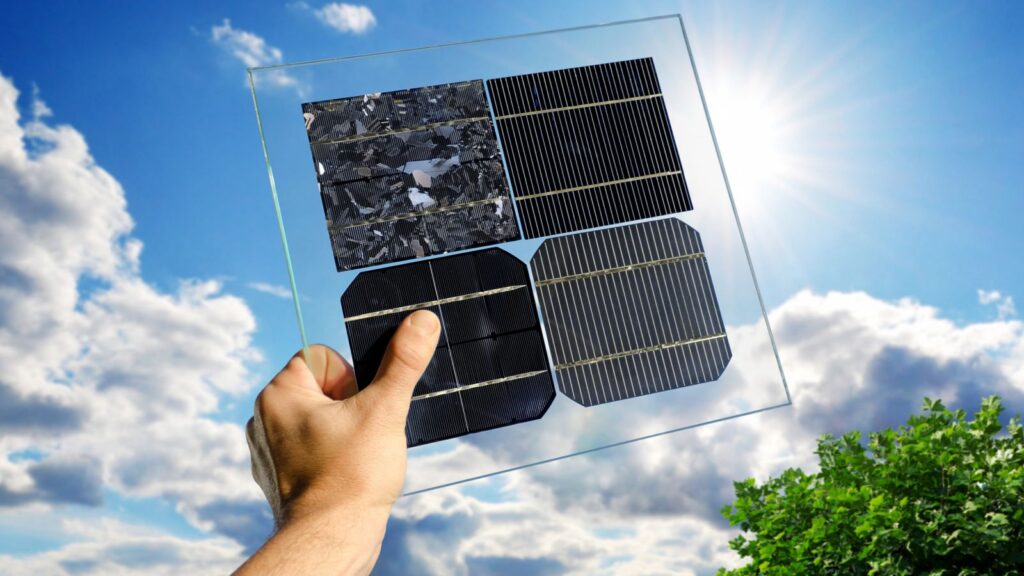

A number of years ago, cell microcracks, hot spots, and PID effects used to be three important factors affecting the performance of crystalline silicon PV modules. In the past few years, with the rapid progress of process technology, equipment and materials, these problems have been substantially improved in the solar panel production process, and the quality of the solar panels leaving the factory is guaranteed.

In recent years, along with the rapid development of the distributed market, the problem of microcracks caused by improper external forces in storage, transport, and installation of modules has become a new problem due to large and small installation teams of mixed quality, or without systematic training, after the modules leave the factory and before and after installation. In the following, we will focus on the causes of microcracks in solar panels during transport, installation and use, the negative effects of microcracks, and the main solutions.

Microcracks refer to the invisible cracks that may be produced in the cell unit that are not easily detectable to the naked eye when the cell (modules) is subjected to large mechanical or thermal stresses.

What causes microcracks to form?

Before and after installation, cell fractures are a regular problem for both solar panel manufacturers and system owners. Mechanical stresses during transport and installation, as well as extreme environmental factors are responsible for microcracks in solar panels.

When an object deforms due to an external cause (force, change in humidity and temperature, etc.), mechanical stress is an internal force that interacts between the parts of the object to try to resist the external cause and return the object from its post-deformation position to its pre-deformation position.

Mechanical stress in the logistics and supply chain process can be brought on by:

(1)Improper packing

(2)Inappropriate modes of transportation

(3)Improper handling methods

Mechanical stress during the installation of a solar PV system can be brought on by:

(1)Using modules as a platform for other equipment or for stepping

(2)Modules crashing or falling as they are raised to the roof

(3)Installation on a surface that isn’t flat could result in the mounting frame twisting and put stress on the module.

The following environmental factors can result in microcracks in solar PV systems as well:

(1)Thermal cycling, or the change in temperature between day and night

(2)Freezing and humidity

(3)Wind loading and cyclic (or dynamic) pressure loads

(4)Abundant snowfall

(5)Hail

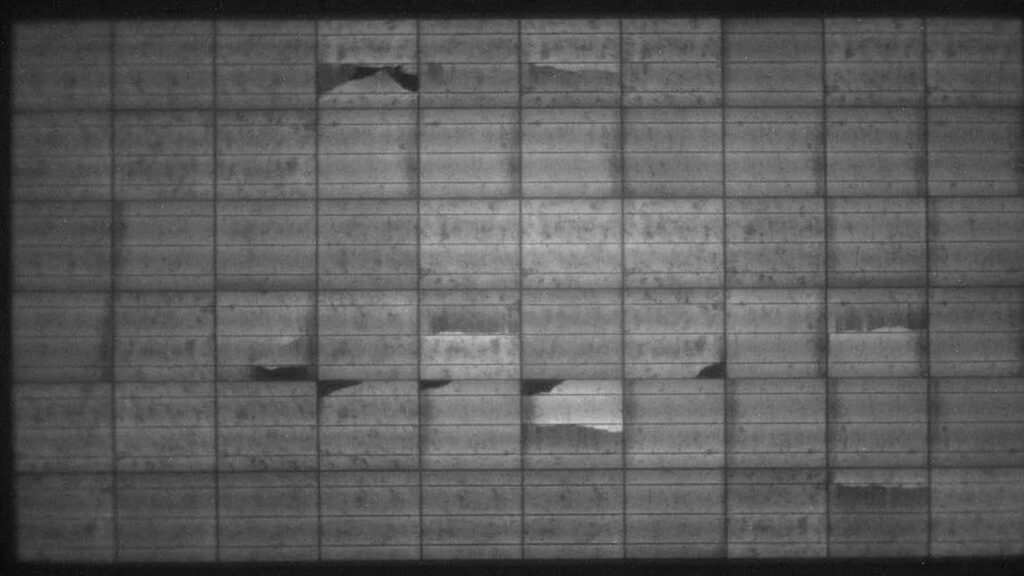

How can microcracks be found after installation?

Utilizing infrared cameras to track temperature variations on the solar panel surface is the most effective technique to locate flaws in solar panels on-site. Cracked solar panel cells develop a high resistance zone with a greater temperature than neighboring cells when exposed to sunlight.

An infrared camera can effectively identify regions with large temperature variations and notify the maintenance crew so they may investigate the questionable panels right away.

Allied Vision’s Korean partner, DISSEM, has helped a leading supplier of solar cell inspection systems develop a cost-effective imaging solution based on near-infrared spectral electroluminescence.

What negative effects do microcracks have?

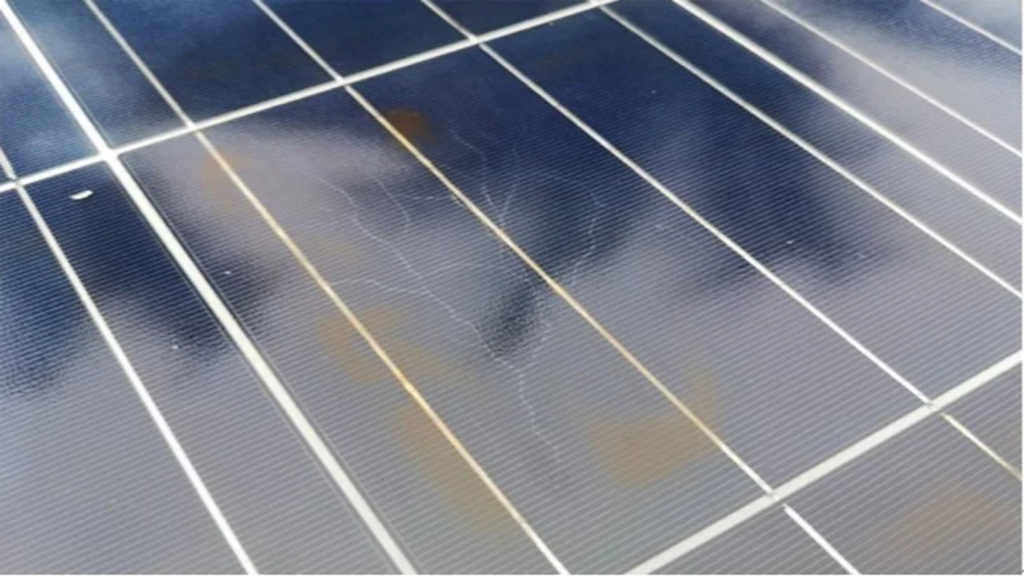

Microcracks can cause loss and may lead to hot spotting effects

According to study, microcracks may cause an electrical separation that leaves some cell components dormant. However, because microcracks can have a range of impacts, including none at all, estimating the power loss brought on by these microcracks is challenging. Rejecting every module that has a microcrack can cause problems, especially when it comes to warranty, but doing so is not required for all of them to still perform at the level of power that is assured for the duration of the module. According to some research, a module with several cracks that do not separate particular areas of the cell can suffer losses of up to 2.5%. For a module with microcracks that do isolate portions of the cell, more losses may occur. Hot spots may also form as a result of microcracks. These happen when a damaged cell’s internal resistance increases and the current travels through it, raising the temperature of the cell. Hot areas have been demonstrated to worsen a cell’s damage.

Microcracks can cause solar panels to lose power and even cause fires

Some microcracks on the solar panel is not obvious, direct look is also unable to see, many people will feel that there is not much problem, you can continue to use, in fact, not, microcracks will cause a direct factor is to cause a decline in solar panel power, there may be some very slight, at this stage of the test power will not be much change, but after a few months, a year of thermal expansion and contraction, the power of the solar panels will drop sharply. Even some serious internal short-circuit will occur causing fire and so on.

How can microcracks be fixed?

Micro-fractures develop within cells and cannot be repaired without a module replacement. However, if the microcracks do not have much impact on the normal operation of solar panels, they can still be used. Therefore, installers and end users should focus on how to scientifically handle, install and use solar panels to prevent microcracks.

How to prevent microcracks?

Three crucial areas must be addressed in order to effectively prevent solar panel micro-cracks: production, transportation and installation, and operating envionment. A key component of the approach is choosing a solar panel manufacturer who realizes the need to prevent microcracks.

A qualified solar panel supplier should fulfil the following conditions:

(1)An organized supply chain

(2)A guarantee-based warranty program for customers

(3)A testing process that guarantees each module is subjected to EL testing

(4)A favorable reputation

How to avoid microcracks when solar panels are placed in warehouse storage?

- To make transport operations easier while avoiding components that are tilted due to hidden fractures or damage, the entire box of components should be piled on a flat, open location.

- The total height of the box stacking must not be more than the height of two boxes. Pay close attention to how the pallet is carefully moved up and down to prevent the pallet corners from being positioned in the air.

- The components should be avoided as much as possible after being set in place before being moved to the construction site to reduce further handling or movement, as this raises the possibility of hidden cracks in the components.

- The components should be covered with materials, such as colorful striped cloth, once they have been arranged neatly to prevent evident damage or hidden cracks brought on by the components tilting or overturning after the site has been subjected to continuous rainwater washout.

- The components must be neatly arranged and placed on a pallet or flat surface when they are temporarily placed there, with the middle components facing upward on the back side and the first and last components facing upward on the glass side. The flat components cannot be placed on more than 18 pieces.

- They must be arranged neatly and temporarily placed diagonally against columns or other things; the supporting objects must be flat, without protrusions, and should not number more than ten pieces.

- When installing solar panels, the solar panels that are temporarily placed somewhere should be loaded on the same day, and the remaining panels need to be placed neatly and flatly or well-protected to avoid collapsing when they are left unattended.

How can microcracks be prevented in secondary handling?

- After the components are unpacked, two people are needed to carry each component to the installation location. This prevents one person from carrying one or more components, lowers the risk of the components falling out of the hand, and lowers the risk of hidden cracks or damage to the components from bumps or shocks.

- Pay attention to your surroundings as you handle the components to prevent running into anything and causing hidden cracks or exploding panels.

- When the parts are ready for installation, lean on the bracket’s beams rather than setting them flat on the floor.

- In order to prevent component damage during the transfer process, components should only be moved by forklift trucks and cranes, and unusual machinery (excavators, loaders, etc.) should be forbidden.

- It is important to cover the components well when they are on the roof to prevent unintentional collisions between them and the walls or their corners, which could result in internal fissures that are difficult to see or outwardly noticeable scars.

How to prevent microcracks during installation?

- Use a top-to-bottom installation procedure for installing the components. Bricks, wood plugs, and other temporary fastening methods should be avoided when mounting the components; at the very least, the upper two bolts should be used for temporary fixing.

- When installing components, installation workers should avoid stepping, sitting, kneeling, pressing, knocking, squeezing, or impacting the components directly. This can result in hidden cracks in the components because of localized stress on the internal battery cells.

- The spring pads must be leveled and the mounting bolts for the components must be tightened properly.

- To prevent the appearance of a pinch angle, the horizontal surface of the pressure block should be firmly in touch with the component frame when utilizing it to fix the components.

Maysun Solar has been specialising in producing high quality photovoltaic modules since 2008. Choose from our wide variety of full black, black frame, silver, and glass-glass solar panels that utilise half-cut, MBB, IBC, and Shingled technologies. These panels offer superior performance and stylish designs that seamlessly blend in with any building. Maysun Solar successfully established offices, warehouses, and long-term relationships with excellent installers in numerous countries! Please contact us for the latest module quotations or any PV-related inquiries. We are excited to assist you.

Reference:

Blessingchi. (2022). How can microcracks damage solar panels. WINAICO. https://winaico.com/blog/microcracks/#How_to_Prevent_Microcracks_During_Production

Micro-Fractures in Solar Modules: Causes, Detection and Prevention. (2020, June 16). Gallagher US. https://www.ajg.com/us/news-and-insights/2020/jan/micro-fractures-in-solar-modules-causes-detection-and-prevention/

Niclas. (2023). Micro Cracks: Causes and Impacts on Solar Panels. Sinovoltaics (Hong Kong Office). https://sinovoltaics.com/learning-center/quality/micro-cracks-causes-and-impacts-on-solar-panels/

Pacheco, M. (2022, November 21). Microcracking kills your solar panels – Age of Awareness – Medium. Medium. https://medium.com/age-of-awareness/microcracking-in-pv-cells-8571980a2b66

Pickerel, K. (2015, May 21). Demystifying the formation of micro-cracks on solar panels. Solar Power World. https://www.solarpowerworldonline.com/2015/05/demystifying-the-formation-of-micro-cracks-on-solar-panels/

RenewSys India. (2023, February 3). Micro cracks in solar modules: Causes, detection and prevention. renewsysworld. https://www.renewsysworld.com/post/micro-cracks-in-solar-modules-causes-detection-and-prevention

What are the dangers of hidden solar panel cracks? How is it caused? How to detect it? How to prevent it? _Equipment_Defects_Testing.(n.d.). Copyright © 2017 Sohu.com Inc. All Rights Reserved.

https://www.sohu.com/a/538122264_121340896

How to prevent hidden cracks after the module is shipped from the factory?(n.d.). Weixin Official Accounts Platform. https://mp.weixin.qq.com/s/dOmIKnZ9-gOu1S-Y6KdTmg

NetEase . (2019, November 5). Nanlai Technology:How to avoid the hidden crack problem of solar panels? Copyright © NetEase. https://www.163.com/dy/article/ET82UUQV05389Q3D.html

What causes hidden cracks in photovoltaic modules_Sunshine Artisan Photovoltaic Network. (n.d.).

http://www.21spv.com/news/show.php?itemid=27317

Near-Infrared Cameras Look for Cracks in Solar Cells – Novus Light Today. (n.d.). https://www.novuslight.com/near-infrared-cameras-look-for-cracks-in-solar-cells_N6758.html

How to Effectively Clean and Intelligently Maintain Photovoltaic Systems for Optimal Performance?

Explore how scientific cleaning and intelligent maintenance can ensure the efficient operation of commercial and industrial photovoltaic systems. Practical advice covers module cleaning frequency, monitoring system configuration, and long-term strategies for energy savings and performance enhancement.

2025 European Photovoltaic Policy Map: Deployment Paths and Regional Strategies for Commercial and Industrial Photovoltaics

A comprehensive analysis of the 2025 European commercial and industrial photovoltaic policy map, focusing on deployment strategies, incentive comparisons, and zero-investment models to support businesses in achieving an efficient and green transition.

Empowering Factories with Solar Energy A Strategic Tool for Controlling Production Electricity Costs

Commercial and industrial solar is becoming a key solution for factories to reduce electricity costs and hedge against price fluctuations. This article systematically analyzes its deployment models, cost advantages, and sustainable value pathways.

How Businesses Can Offset Carbon Taxes with Solar Power

This article analyzes the latest carbon tax policies and photovoltaic deduction strategies, helping European businesses legally reduce taxes, increase profits through solar investment, and achieve a win-win situation for both economy and environment.

Forecast and Response: Seizing the Next Decade’s Growth Dividend in Europe’s Commercial and Industrial Photovoltaics Market

Maysun Solar analyzes the growth trends of commercial and industrial photovoltaics in Europe over the next ten years, from policies and ESG to technological innovation, helping companies seize the initiative in the energy transition.

How to Calculate Solar System ROI and Optimize Long-Term Returns?

Solar power is becoming a key solution for businesses to reduce costs and improve efficiency. Accurately calculating ROI and optimizing long-term returns are essential to maximizing investment value.