Table of Contents

What is an IBC solar panel?

The IBC (Interdigitated Back Contact) cell is an innovative technology designed to reposition the metal contacts of a solar cell’s positive and negative poles to the rear side of the cell. This groundbreaking approach enhances the efficiency and performance of the solar cell by optimizing the arrangement of these contacts, leading to improved electrical conductivity and overall effectiveness in energy conversion.

What are the challenges of high-temperature weather for solar panels?

1.Efficiency Decline:

High temperatures can lead to a decrease in the photovoltaic conversion efficiency of solar panels. The typical efficiency degradation of silicon-based solar panels under elevated temperatures is a common issue. This is because the increase in temperature results in enhanced scattering losses of charge carriers, slowing down the movement of electrons, consequently reducing the overall photovoltaic conversion efficiency.

2.Thermal Distortion:

Elevated temperatures may cause thermal distortion in solar panels, altering their shape. This could adversely affect the structure and material performance of solar panels, thereby compromising their mechanical stability.

3.Thermo-Optical Effects:

In high-temperature environments, solar panels are more susceptible to thermo-optical effects, where a portion of the sunlight is converted into heat energy. This leads to a further increase in the panel’s temperature, creating a positive feedback loop that makes the panel more prone to overheating.

4.Electrolyte Loss:

For certain types of solar cells, high temperatures may result in the loss of electrolyte, thereby impacting the stability and performance of the cells. This is particularly crucial for specialized cells like dye-sensitized solar cells.

5.Reduced Lifespan:

Prolonged operation in high-temperature conditions can accelerate the aging process of solar panels, diminishing their lifespan. This is primarily due to the fact that elevated temperatures expedite material degradation and wear and tear of internal components within the solar cells.

Why are IBC solar panels suitable for high-Temperature environment?

Low temperature coefficient

The solar panel’s low-temperature coefficient signifies how its performance parameters change with each degree Celsius of operating temperature variation. This coefficient gauges how sensitive the panel’s electrical performance is to operating temperature fluctuations. For example, IBC solar panel has a temperature coefficient of -0.29%/°C, it means that for every one-degree Celsius rise in operating temperature beyond the Standard Test Conditions (STC) of 25°C, the IBC solar panel’s peak power output decreases by 0.29%.

Below, we compare the power degradation of two different temperature coefficient solar panels (PERC vs. IBC) under high-temperature conditions at 40°C.

1. IBC Solar Panels (Temperature Coefficient of 0.29%/°C):

Increase in operational temperature: 80°C – 25°C = 55°C.

Power Degradation = 55°C × 0.29%/°C = 15.95%.

2. PERC Solar Panels (Temperature Coefficient of 0.34%/°C):

Increase in operational temperature: 55°C.

Power Degradation = 55°C × 0.34%/°C = 18.7%.

In elevated temperature conditions, IBC and PERC solar panels exhibit power degradation rates of 15.95% and 18.7%, respectively. This highlights the superior performance retention of IBC solar panels under high-temperature conditions. Furthermore, as operational temperatures rise, the difference in power degradation between these two panel types becomes more pronounced. Therefore, IBC solar panels are the optimal choice for hot weather conditions.

Good weathering resistance (thermal stress)

The term “good weathering resistance” in the context of solar panels, also known as excellent thermal stress performance, refers to the ability of solar panels to maintain their performance and stability under various climatic conditions, including high-temperature environments. This is a crucial feature because solar panels are often required to operate in diverse weather conditions, and in some regions, they may encounter hot weather.

The advanced full back-contact design of Interdigitated Back Contact (IBC) solar panels is closely linked to their thermal stress resistance. A key aspect of this design involves relocating the positive and negative electrodes of the solar panel to the rear, eliminating the need for front-side ribbons and metal grid lines. This unique design significantly mitigates the occurrence of thermal stress.

Firstly, IBC solar panels, devoid of metal grid lines and ribbons on the front side, experience less thermal expansion and contraction during temperature fluctuations. This reduction in thermal stress on the front side enhances the overall stability and durability of the solar panel.

Additionally, the design of IBC solar panels optimizes the efficiency of current transmission within the solar cell, thanks to improved back-side electrode contact with the solar cells. This effectively reduces resistive losses and enhances the overall performance of the solar panel.

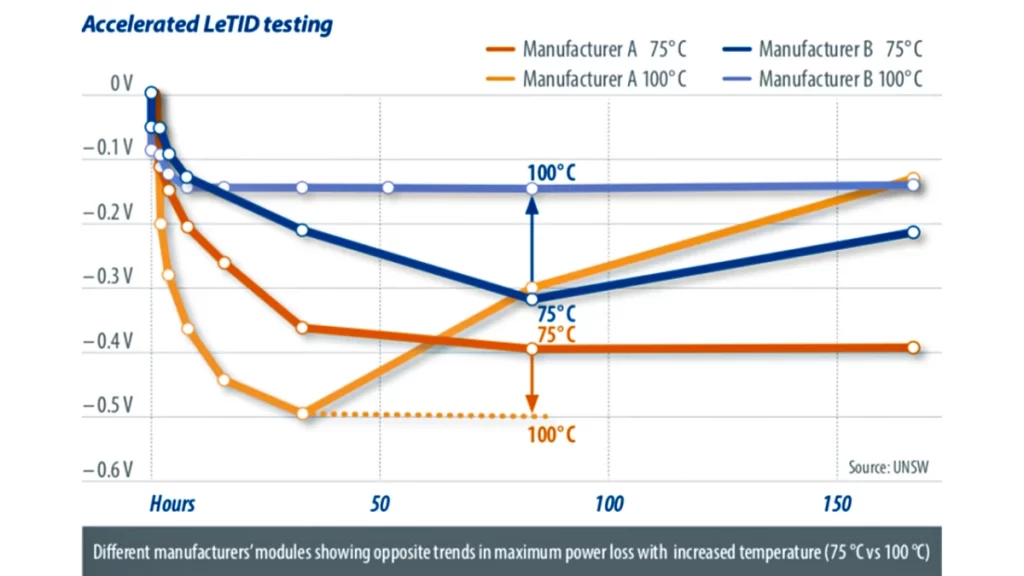

LeTID effect:

LeTID (Light and Elevated Temperature Induced Degradation) is an effect that impacts the performance of solar panels, primarily occurring when solar panels are exposed to light and high-temperature conditions. The LeTID effect can lead to a reduction in the performance of solar panels, affecting their long-term stability.

Reasons why IBC performs better in terms of anti-LeTID:

1.Electrode Position: The electrodes of IBC solar panels are located on the back rather than the front, helping to reduce the number of charge-capturing centers on the surface of the solar cell. Charge-capturing centers, which are defects or impurities, can capture and trap charges, leading to a decline in the solar cell’s performance. By moving the electrodes to the back, the IBC design reduces the number of charge-capturing centers that may form on the front surface of the solar cell, thereby slowing down the occurrence of the LeTID effect.

2.Current Distribution: The IBC structural design involves the cross-arrangement of solar cell electrodes, promoting a more uniform distribution of current across the surface of the solar cell. This helps to reduce localized hotspots and mitigate the occurrence of LeTID. In comparison, some other structures may result in the concentration of current in specific areas, increasing the risk of LeTID.

PVF film

IBC (Interdigitated Back Contact) solar panels utilize a design featuring a TPE backsheet with a PVF (Tedlar) film and an enhanced EPE adhesive film, contributing to improved high-temperature adaptability.

This enhancement yields several benefits, including:

1.Thermal Stability: The PVF (Tedlar) film typically possesses high thermal stability, maintaining its performance and structural stability in high-temperature environments. This helps the solar panels operate normally under high-temperature conditions, mitigating the risk of performance degradation.

2.Low Water Permeability: TPE backsheets often exhibit low water permeability, meaning that moisture is less likely to penetrate the interior of the solar panels. In high-temperature conditions, moisture ingress can lead to a decline in performance, but the use of low water-permeable materials helps alleviate this issue.

3.High-Temperature Resistant Adhesive Film: The enhanced EPE adhesive film may have high resistance to elevated temperatures, enabling it to withstand stress and deformation under high-temperature conditions. This contributes to maintaining the stable shape and performance of the solar panels in high-temperature environments.

What is the future of solar energy in high temperature environment?

1.Enhanced High-Temperature Adaptability:

IBC solar panels exhibit greater stability in high-temperature environments compared to traditional panels. Their design minimizes internal resistance and heat losses, contributing to the maintenance of higher conversion efficiency under elevated temperatures.

2.Optimized Energy Conversion:

IBC technology enhances the photovoltaic conversion efficiency of solar panels. While traditional panels may experience performance degradation in high temperatures, IBC solar panels excel in addressing such challenges, providing a more stable energy conversion performance.

3.Success in Real-World Applications:

There have been successful applications of IBC solar panels in High-Temperature weather. These cases offer tangible data support, affirming the outstanding performance of IBC technology in challenging high-temperature environments.

Since 2008, Maysun Solar has been specializing in manufacturing high-quality photovoltaic modules. Choose from our large selection of full black, black frame, silver, and glass-glass solar panels. These panels are made using MBB, IBC, and shingled technologies. These panels provide superior performance and stylish designs, which will blend in well with any building. Maysun Solar has established offices, warehouses, and long-term relationships with outstanding installers in many nations! For the latest solar panel pricing or any questions about photovoltaics, please contact us. We are eager to provide you with assistance.

Empowering Factories with Solar Energy A Strategic Tool for Controlling Production Electricity Costs

Commercial and industrial solar is becoming a key solution for factories to reduce electricity costs and hedge against price fluctuations. This article systematically analyzes its deployment models, cost advantages, and sustainable value pathways.

How Businesses Can Offset Carbon Taxes with Solar Power

This article analyzes the latest carbon tax policies and photovoltaic deduction strategies, helping European businesses legally reduce taxes, increase profits through solar investment, and achieve a win-win situation for both economy and environment.

Forecast and Response: Seizing the Next Decade’s Growth Dividend in Europe’s Commercial and Industrial Photovoltaics Market

Maysun Solar analyzes the growth trends of commercial and industrial photovoltaics in Europe over the next ten years, from policies and ESG to technological innovation, helping companies seize the initiative in the energy transition.

How to Calculate Solar System ROI and Optimize Long-Term Returns?

Solar power is becoming a key solution for businesses to reduce costs and improve efficiency. Accurately calculating ROI and optimizing long-term returns are essential to maximizing investment value.

Will Agrivoltaics Affect Crop Growth?

Agrivoltaics combines solar energy and agriculture to reduce up to 700 tons of CO₂ per MW, improve water use, and boost crop growth for sustainable farming.

6.5 Billion Loss Hits Photovoltaics: Reshaping or Elimination?

In 2025, the photovoltaic market may see a turnaround as some companies take early action. A €6.5 billion loss is driving businesses to explore new growth areas like energy storage and hydrogen. Which giants will break through? Industry transformation is accelerating!