A solution to the rising need for effective solar panels is the creation of solar cells using innovative technology. With the help of this technology, solar cells can operate more effectively, giving you access to enhanced solar modules for residential and commercial use. Did you know that solar panels with busbars and multi-busbar exist? If not, then today you will learn about MBB technology. What is the influence of dash line pattern busbars on solar cells?

MBB has experienced significant growth in recent years

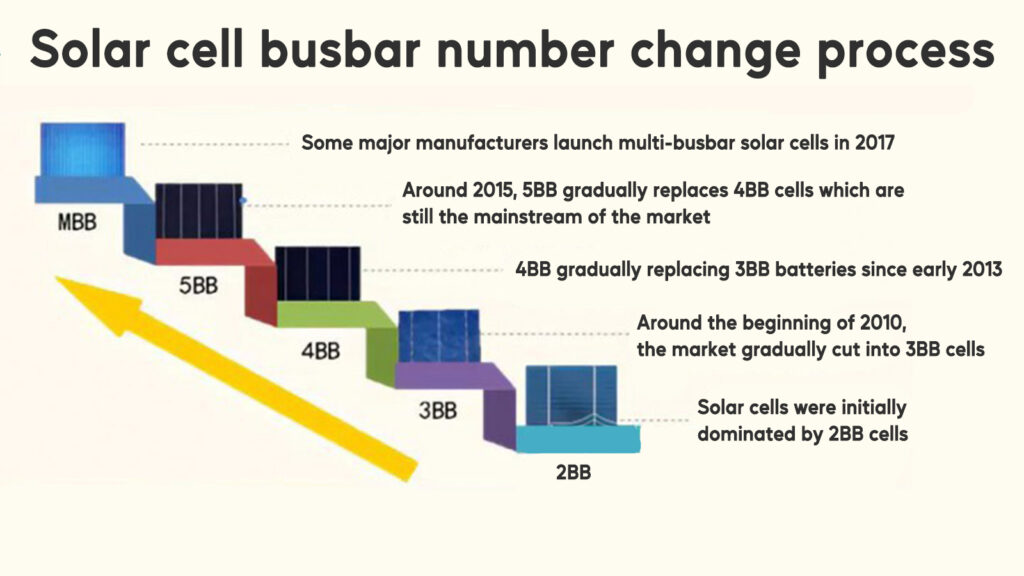

In recent years, solar panel technology has developed rapidly. After 11 years of development, MBB technology has also rapidly changed from laboratory research level to market scale production.

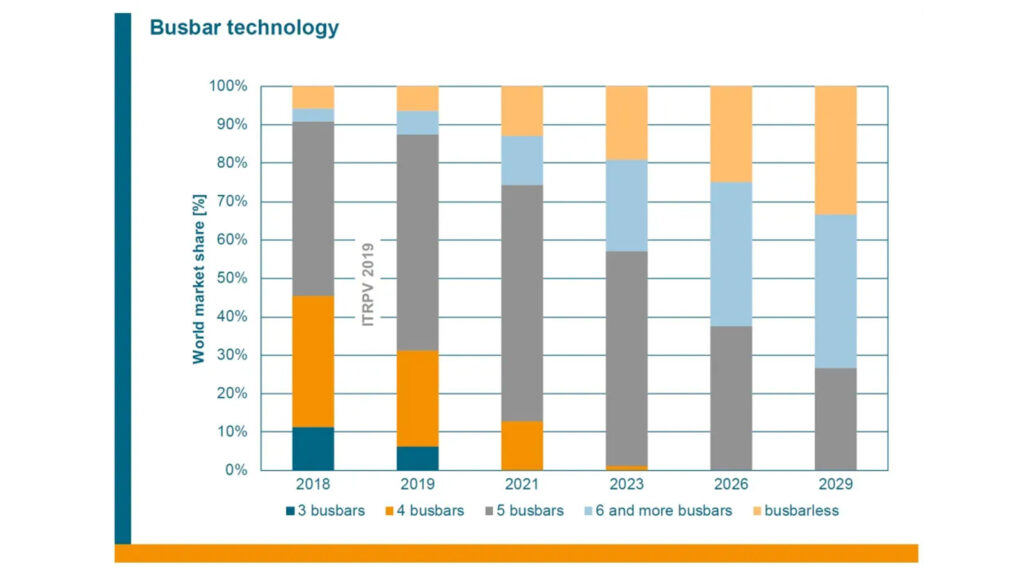

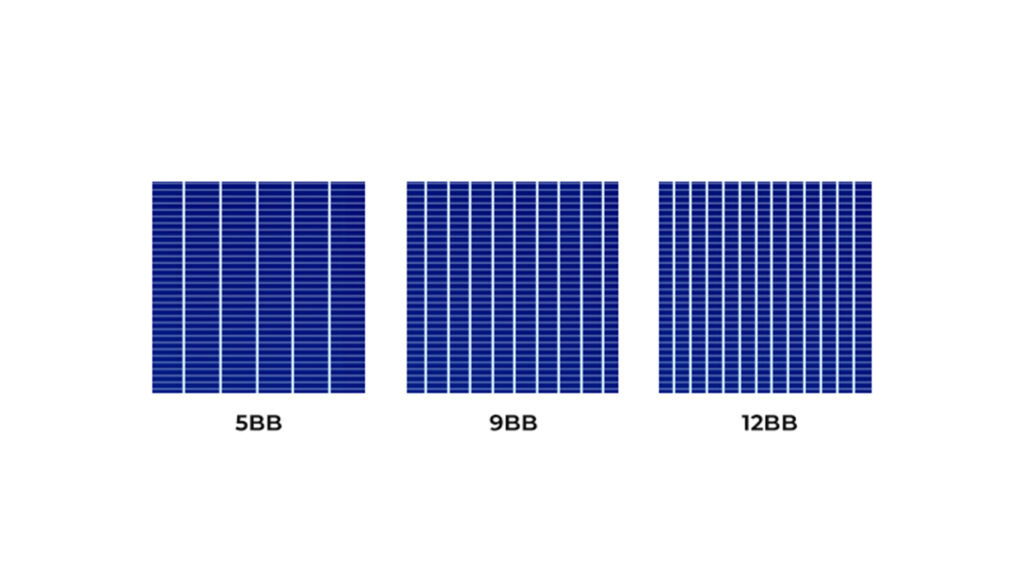

One of the most noticeable features of modern solar panel design is the use of MBB solar cells. Recently, the industry standard for solar panels has increased from 2BB to 6BB. Several manufacturers have stepped up their game, expanding the size of their panels to 9BB and even 16BB. They are particularly interested in PERC Solar Cell panel designs that maximize front-side busbar utilization. Therefore, multiple busbars are a very beneficial thing when constructing solar panels with efficiency as a goal.

MBB is gaining popularity and will likely become widespread. Popular MBB are replacing others. Multi ribbon and multi wire busbars improve cell metallization connections, lowering cell spacing and enhancing solar cell performance. The shorter finger length and increased light in-coupling reduce electrical and optical losses, saving roughly 2.4 g for the 60 cell module compared to ribbon technology.

MBB+half-cut, is now more popular in the market Higher-end products, it is more than the traditional 5BB whole piece, both half-cut and MBB advantages, is the market high-end products Mainstream is 9BB+half-cut, 12BB+half-cut, 10BB+half-cut and so on. It is the product with greater potential in the back, and it is the latest high-end product with new technology.

Screen printing technology, wafer size, and wafer cost have all improved in recent years. As a result, silver paste costs more, multi-busbar technical complexity decreases, and cost performance rises.

What do Busbars do in Solar Panels? What does MBB Solar Cell mean?

We typically print busbars flat and solder flat ribbons onto them. Busbars deliver generated current to the cells, whereas ribbons transport current away from the cell. In the front of the solar cell, MBB transfers current from the fingers through connecting ribbons to the environment. The bifacial property of PERC cells—the ratio of front power to rear power—can be improved by the multi-busbar. The solar cell exhibits the following features by utilizing the multi busbar technique.

- The cell’s shading towards the rear side has decreased. l

- There is a small rear aluminum fingers print. l

- The bifacial light-harvesting function has been improved.

Busbars are rectangular strips printed on both sides of solar cells. Solar cells have a narrow, rectangular Busbar on both sides. The complete solar cell strip transmits electricity. This strip separates cells so photons can pass directly to the solar inverter and be converted into AC. Silver-plated copper busbars improve front conductivity and back oxidation.

Solar cell efficiency affects busbar number. MBB solar cells include multiple busbars, reducing series resistance. MBB solar cells, especially 5BB cells, are in high demand.

Thinner wires are better because metal electrodes obstruct the cell and diminish light area, and silver is expensive. Thinner wires lower conductive cross-sectional area and increase resistance losses. A solder strip connects the module cells to the main grid, thus grid wire alterations need soldering process changes. The grid wire must balance shading, conductivity, and cost.

How does MBB work?

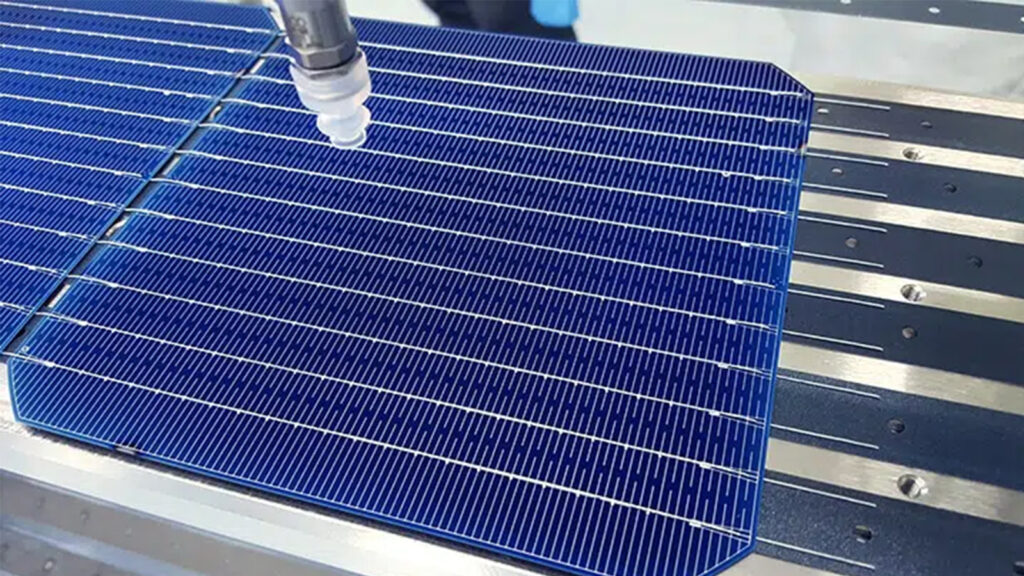

These steps will explain how MBB works:

- The fingers gather the produced current and transport it to the busbars. The fingers are parallel, ultra-thin metal grids that are attached to the busbars.

- The current from a single string of cells is collected by tab wires. Tab wires are typically attached to busbars via soldering.

- The electricity from the cells is sent to the junction box through bus wires. Parallel bus wires link a group of interconnected cells.

The current from each string of cells is collected by busbars, and then the combined current is sent to the inverter.

Working Principle of MBB:

The MBB approach actively reduces resistive losses by decreasing the current flowing through both the fingers and the busbars. By printing more busbars on a wafer, we effectively shorten the space between them, resulting in a shorter path for the current to flow through the fingers. This reduction in length significantly contributes to the decrease in series resistance losses. Since the resistive power loss (Ploss) is proportional to the square of the current (I) multiplied by the resistance (R), halving the current leads to a four-fold reduction in resistive losses.

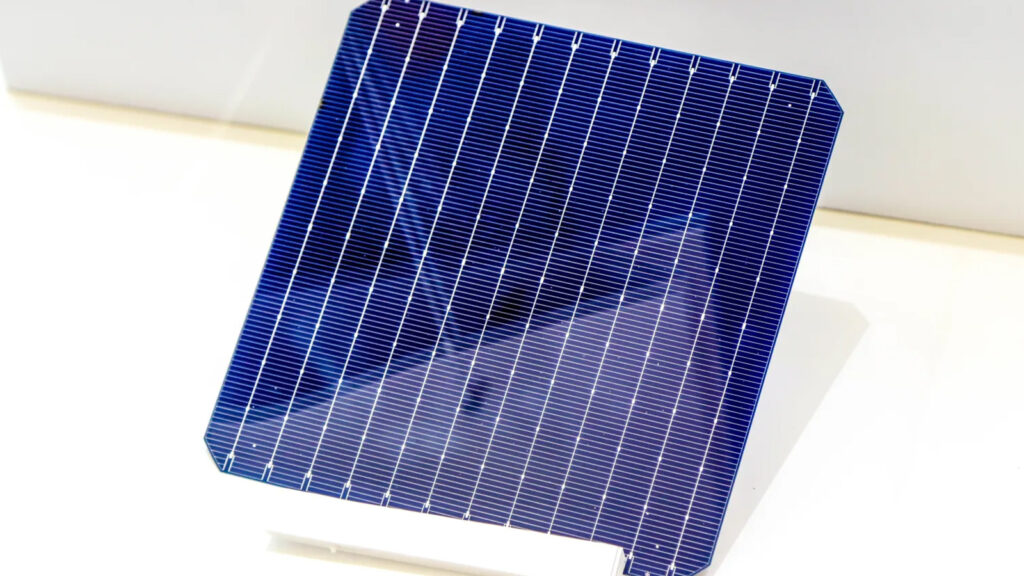

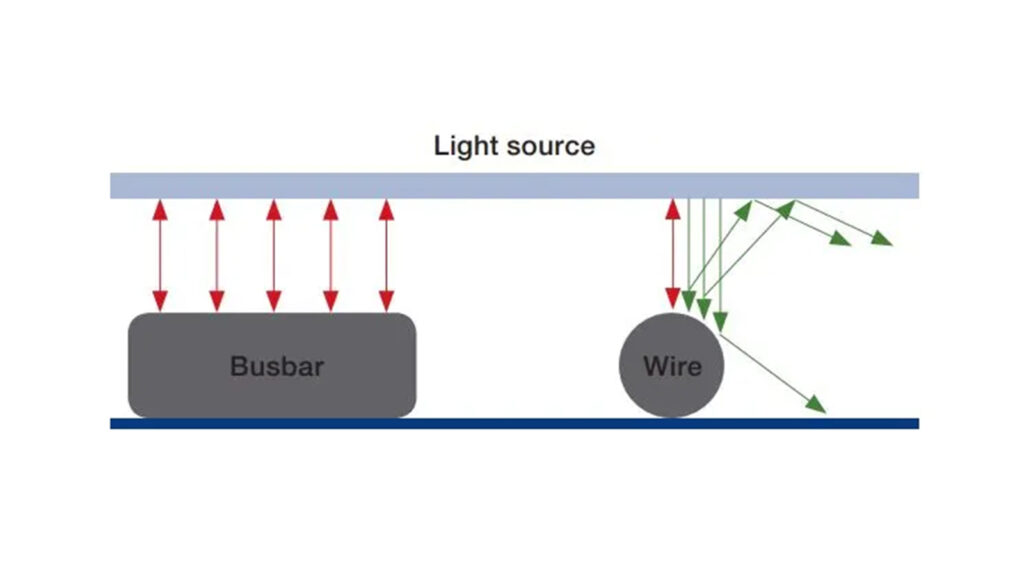

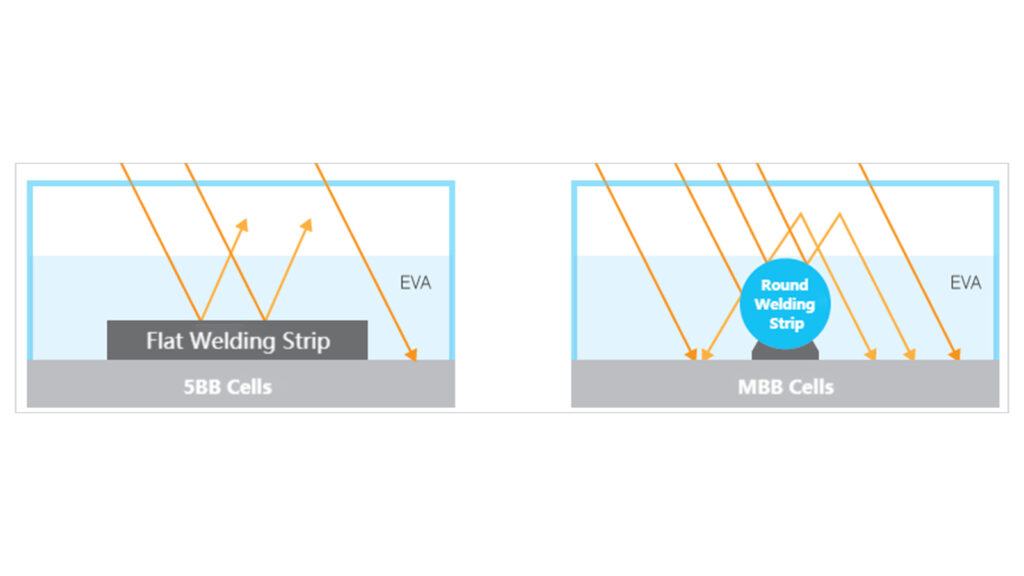

MBB differs from “more-busbars” in cross-section and function. MBB transmits current away from the cell using thin, rounded copper wires instead of flat busbars and soldered ribbons, which create shading and resistive losses. MBB wires actively transfer current from fingers to interconnecting ribbons outside the solar cell’s front surface. Cell ribbons are superfluous. The figure below shows how MBB’s rounded cross-section boosts solar cell performance.

MBB may improve PERC cell bifaciality as bifacial technology grows globally. Front-to-rear power ratio defines bifaciality. MBB lets us print smaller rear aluminium fingers, minimizing shadowing on the cell’s back side and boosting light harvesting from both sides. MBB also reduces microcracks and increases the possibility of cracked areas keeping electrical contact with the rest of the cell, enhancing performance and reliability.

Advantages of MBB Technology

1.Manufacturing technology is maturing and PV module reliability is improving

Scientists investigating MBB solar panels to boost solar cell energy. Busbars increase solar cell efficiency and dependability. Silver is used in most solar panels’ wiring due to its high conductivity, despite its high price. New techniques are being developed to assist lessen the solar panel’s reliance on silver without sacrificing performance. Reduce expenses while maximizing results! Multi-busbar solar panel design reduces silver. Screen-printed Ag front-side metallization costs. New busbars improved the 3BB cell design. Busbars save Ag paste and boost module efficiency. Tin soldering backside Ag/Al pads reduces silver. Busbars make solar cell output easier.

2.Reducing the risk of hidden cracks

The dependability of modules was improved. Even if the multi-grid cell includes hidden cracks and fragments, the enhanced grid density and tiny spacing allow it maintain better power generation performance. After welding, the weld strip spreads out uniformly across the cell, relieving stress on the cell’s encapsulation and improving its mechanical qualities.

3.Increased efficiency (less welding tape shading, more light)

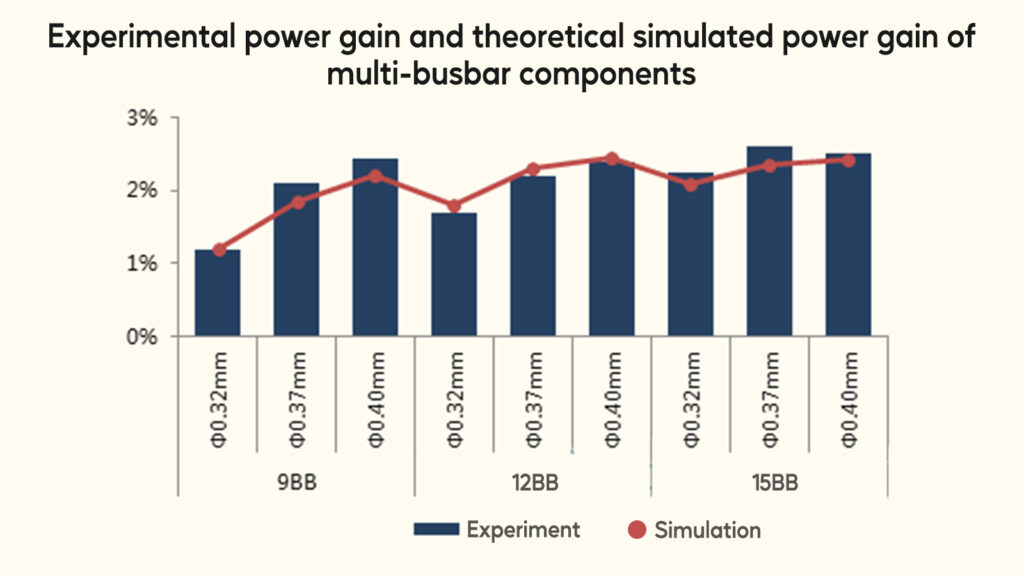

The module power increases by 5-10% due to reduced electrode resistance and shading. Most of the multi-busbar cells are designed with 9/12 busbars, which increases the current collection capacity of the busbar and effectively reduces the module operating temperature, improving the long-term power generation performance of the module, increasing module efficiency by 2.5% and power by 5-10W.

4.MBB solar panels are more aesthetically pleasing than regular solar panels

Regardless of how many main grids there are, the area of the main grid lines is actually the same when we design the cell. So the more main grids there are, the thinner the lines are, and the better they look from a distance.

5.Weather resilience

MBB cells are one of the well-known trends in solar panel design. MBB cells break the solar cell down into smaller pieces and are more resistant to overload and environmental factors. Additionally, it prevents cells’ bus bars’ microcracks. Compared to regular cells, MBB are more reliable and long-lasting under cracking conditions.

6.Optical performance

5BB Modules employ rectangular plates, but MBB modules use circular ribbons, which decrease the shadowing area and repeatedly reflect the incident light as illustrated in the Figure, increasing optical performance and subsequently power generation. The cross-section and purpose of MBB and the more bus bar method, however, are distinct. Bus bars are typically printed flat, and because they need soldered flat ribbons to transmit current from the cell, greater resistive losses arise. MBB are spherical, thin copper wires, however unlike ribbons that span the solar cell, they transport electricity from the fingers to connecting ribbons that are located outside the cell’s front surface.

Although MBB technology has many advantages, it still has shortcomings, for example, its production process is more complex than the traditional 5BB process. Its cost increase of 0.5-1 euro cent / W. But experts are working on the most efficient and least costly ways to reduce its price.

Maysun Solar is committed to providing advanced, differentiated, and cost-effective products to our clients, such as shingled, bifacial and half-cut 9BB 10BB 12BB large-size and high-efficiency solar panels.

As a pioneer in MBB technology, Maysun Solar has been at the forefront of the industry in the research and development and mass production of MBB, and has accumulated a wealth of experience in the field of MBB technology, which has been applied to TwiSun, VenuSun and other series of solar panels.

Since 2008, Maysun Solar has specialized in producing high quality photovoltaic modules. We have a wide variety of full black, black frame, silver, glass-glass solar panels which use half-cut, MBB, IBC and Shingled technologies to choose from, and they offer superior performance and stylish designs that will blend in perfectly with any building. Maysun Solar has successfully established offices, warehouses, and long-term relationships with excellent installers in numerous countries! Please feel excited to contact us for the latest module quotations or any PV-related inquiries.

How Businesses Can Offset Carbon Taxes with Solar Power

This article analyzes the latest carbon tax policies and photovoltaic deduction strategies, helping European businesses legally reduce taxes, increase profits through solar investment, and achieve a win-win situation for both economy and environment.

Forecast and Response: Seizing the Next Decade’s Growth Dividend in Europe’s Commercial and Industrial Photovoltaics Market

Maysun Solar analyzes the growth trends of commercial and industrial photovoltaics in Europe over the next ten years, from policies and ESG to technological innovation, helping companies seize the initiative in the energy transition.

How to Calculate Solar System ROI and Optimize Long-Term Returns?

Solar power is becoming a key solution for businesses to reduce costs and improve efficiency. Accurately calculating ROI and optimizing long-term returns are essential to maximizing investment value.

Will Agrivoltaics Affect Crop Growth?

Agrivoltaics combines solar energy and agriculture to reduce up to 700 tons of CO₂ per MW, improve water use, and boost crop growth for sustainable farming.

6.5 Billion Loss Hits Photovoltaics: Reshaping or Elimination?

In 2025, the photovoltaic market may see a turnaround as some companies take early action. A €6.5 billion loss is driving businesses to explore new growth areas like energy storage and hydrogen. Which giants will break through? Industry transformation is accelerating!

What’s New in Solar Energy (March 2025)

March’s solar news highlights include rooftop solar meeting two-thirds of global demand, China’s market reforms potentially boosting solar demand and module prices, France revising solar targets in PPE 3, and challenges in Europe with declining capture rates and price volatility.