Introduction

As photovoltaic technology continues to advance, the photovoltaic module market has evolved from high current to low current. High current photovoltaic modules have garnered attention for their high power output, but the associated risks and losses cannot be ignored. In contrast, low current photovoltaic modules are increasingly seen as a wiser choice due to their advantages in safety, efficiency, and compatibility. This article will analyze the risks and losses of high current photovoltaic modules and explore the unique benefits of low current photovoltaic modules.

Table of Contents

The Emergence of High Current Photovoltaic Modules

Levelized Cost of Energy (LCOE) is a core metric for assessing photovoltaic projects. On the module side, efficiency, power, and generation capacity play critical roles, and improving the power and efficiency of photovoltaic modules can effectively reduce LCOE. As early as 2009, the maximum power of photovoltaic modules in the industry was only 290W. After more than a decade of development, the power of photovoltaic modules has risen to over 500W, with some exceeding 600W. The main paths to improving module power include advancements in cell technology that enhance conversion efficiency, optimization of module layout and auxiliary materials, and increasing wafer sizes. Initially, mass-produced solar cells were based on 125mm wafers, which later evolved to 156mm, 156.75mm, 158.75mm, 166mm, and now to 182mm and 210mm. The advent of 182mm and 210mm large-size wafers in 2020 not only brought a significant increase in module power but also markedly increased the operating current of photovoltaic modules.

Generally, the rationale behind increasing wafer size includes two main points: firstly, it can effectively reduce the cost per watt of wafers and solar cells, thereby lowering the production cost of photovoltaic modules; secondly, increasing wafer size can enhance module power, thereby reducing the Balance of System (BOS) cost. However, any gains are within a certain range; when the cell size and current increase to a certain extent, the associated risks, hazards, and losses may outweigh the benefits.

Risks and Losses of High Current Photovoltaic Modules

1. Production and Quality Risks of High Current Photovoltaic Modules

In the production process, as the cell size increases, the product yield tends to decrease due to increased manufacturing difficulty. The yield of large-size wafers and cells in the initial production stages may not reach the level of original products, and some issues caused by size increase may not be perfectly resolved as the process matures. Additionally, oversized wafers can hinder the development of thinner cells, and the increased size of photovoltaic modules can impede cost reduction in frames and glass, impacting production costs. Furthermore, the increase in wafer and module size also increases mechanical load risks, making transportation and installation more challenging and placing higher demands on the support structures, affecting the quality throughout the product and system lifecycle.

2. Impact of High Current Photovoltaic Modules on Power Generation

(1) Cable Line Loss

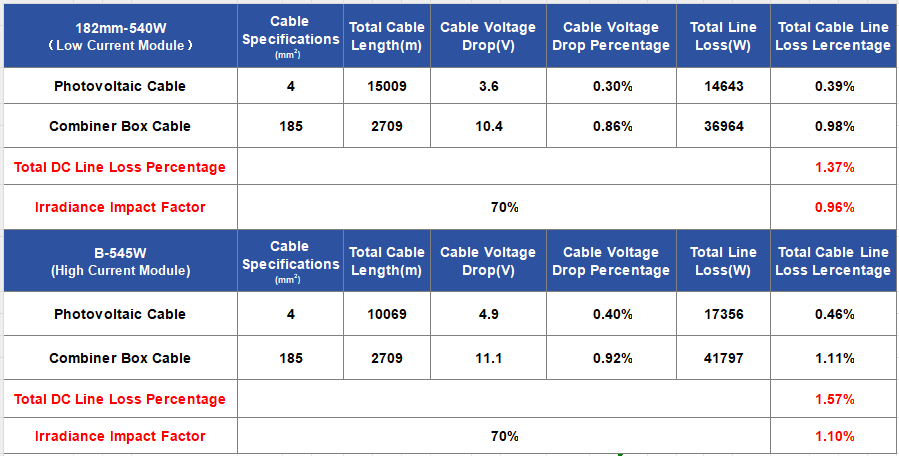

Based on a 100MW project, we compared the line loss of 182mm photovoltaic modules (operating current around 13A) and ultra-high current photovoltaic modules (operating current around 18A). Under standard test conditions (STC), using the same 4mm² cable specification, the ultra-high current photovoltaic module scheme had about 0.2% higher DC side line loss compared to the 182mm module scheme. Even assuming the actual application environment irradiance is 70% of STC conditions, there is still a line loss difference of about 0.14%. In systems using bifacial photovoltaic modules, the current increase of bifacial modules compared to monofacial modules can be 10%-20%, further amplifying the line loss difference.

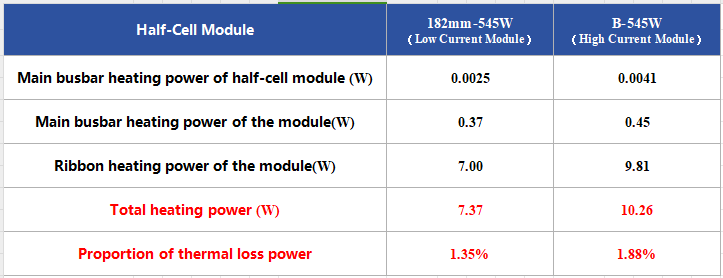

(2)Module thermal power Loss

We also conducted related research and calculations on the thermal power loss of photovoltaic modules: the thermal power loss proportion of ultra-high current photovoltaic modules is 0.53% higher than that of 182mm photovoltaic modules. For a 3GW scale project, due to direct thermal power loss, ultra-high current photovoltaic modules will generate 20 million kWh less per year than 182mm photovoltaic modules.

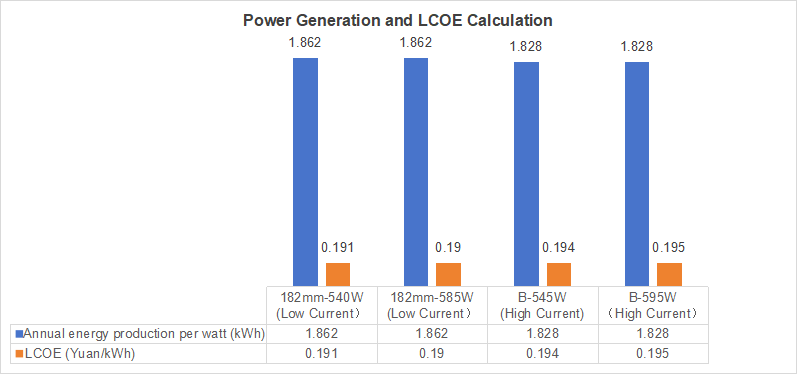

(3)Power Generation and LCOE Calculation

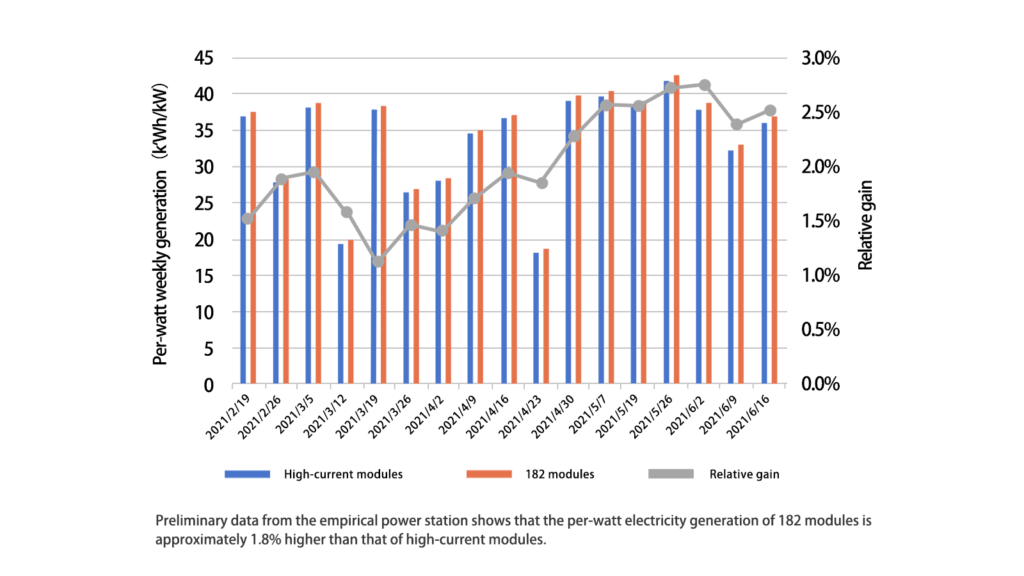

Simulation results show that the power generation of 182mm photovoltaic modules is 1.8% higher than that of ultra-high current modules, at 1.862 kWh/Wp/year. In terms of LCOE, the 182mm photovoltaic modules are 0.03-0.05 Yuan/kWh lower than the ultra-high current modules, at 0.19 yuan/kWh.

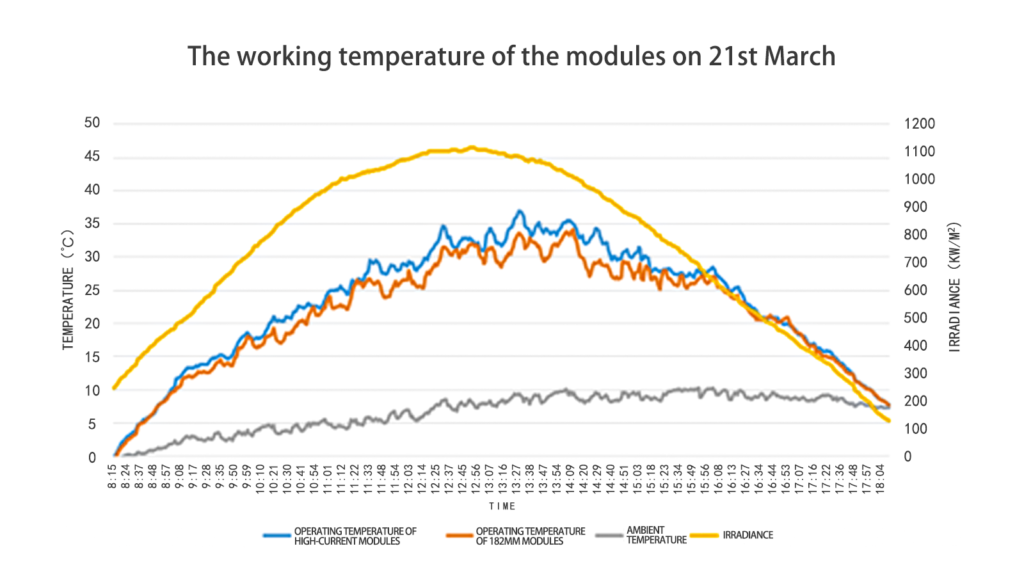

(4)Empirical Analysis of Ultra-High Current Photovoltaic Modules

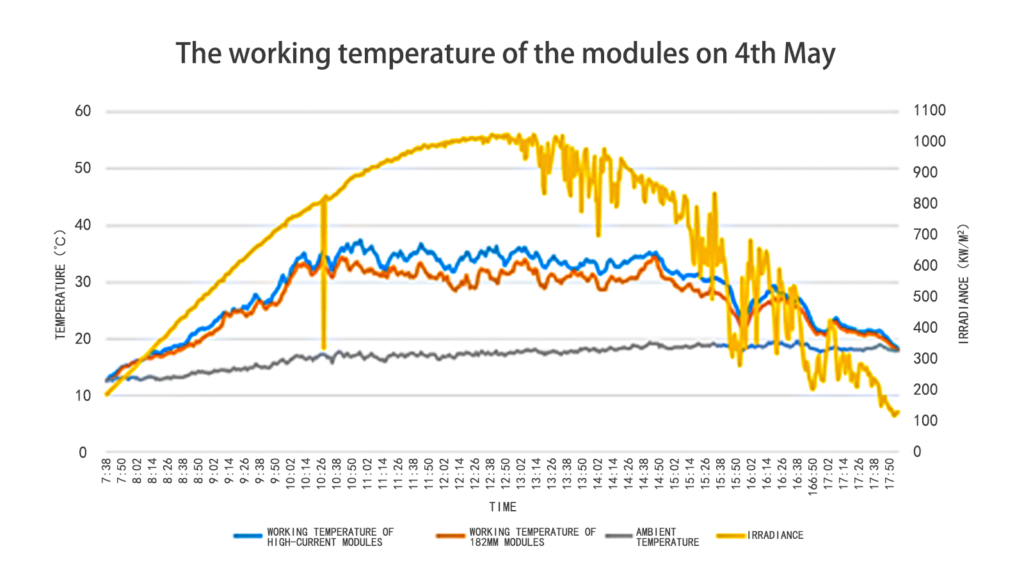

To fully study the power generation performance and operating temperature differences of different photovoltaic modules, a leading brand, in collaboration with TÜV Nord, conducted an outdoor empirical project at the National Photovoltaic Experimental Base in Yinchuan in February 2021. Empirical data showed that under high irradiance weather, due to more energy being converted into heat on the ribbons, the operating temperature of ultra-high current photovoltaic modules was on average 1.8°C higher than that of 182mm photovoltaic modules, with a maximum temperature difference of about 5°C. This is mainly because the high operating current of photovoltaic modules leads to significant thermal losses on the cell surface metal electrodes and ribbons, increasing the module’s operating temperature. As is well known, the output power of photovoltaic modules decreases with increasing temperature, with power decreasing by about 0.35% for every 1°C increase in temperature; combined with multiple factors, empirical data shows that the single-watt power generation of 182mm photovoltaic modules is about 1.8% higher than that of ultra-high current modules.

3. Electrical Safety Risks of High Current Photovoltaic Modules

Photovoltaic modules are electrical devices that encapsulate solar cells with glass, backsheet, EVA, or POE, and then transmit the generated DC electricity through junction boxes, cables, and connectors. For the entire photovoltaic module, junction boxes and connectors, though inconspicuous small components, can cause significant safety hazards if they fail.

(1)Junction Box Heating Risk

According to statistics from authoritative third-party organizations, power station failures (especially fires) caused by photovoltaic modules are mostly related to junction boxes and connectors. Therefore, the junction box is a critical technical point in module design, especially for high current photovoltaic modules, where the current-carrying capacity of the diodes in the junction box is crucial. The following image shows the situation where junction box heating caused connector burning.

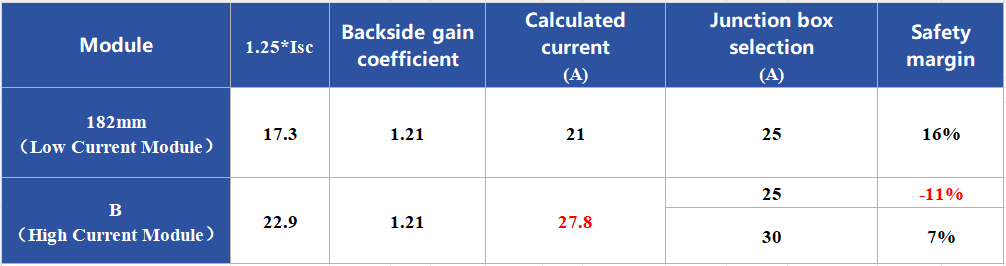

To ensure the current-carrying capacity of the diodes in the junction box, for monofacial photovoltaic modules, it is recommended that the rated current of the junction box should be greater than 1.25 times the short-circuit current (Isc). For bifacial photovoltaic modules, a 30% bifacial gain and about 70% rear-side ratio should also be considered. The 182mm bifacial photovoltaic modules use mature 25A rated current junction boxes on the market, maintaining about 16% safety margin, ensuring the long-term reliability of high current photovoltaic modules. Larger current modules require higher-rated current junction boxes (30A). However, even with 30A junction boxes, the safety margin of ultra-high current photovoltaic modules is relatively low, and the risk of overload increases significantly under high irradiance and high-temperature conditions.

(2)Cable Heating Risk

Based on the IEC 62930 standard, we conducted current-carrying capacity research and calculations on photovoltaic cables. In general ground-mounted or distributed rooftop power plants, 4 mm² cables can meet the application needs of 182mm photovoltaic modules and ultra-high current photovoltaic modules. However, when some distributed rooftops reach temperatures of 70°C, if ultra-high current photovoltaic modules do not use more expensive 6mm² photovoltaic cables, the cables may overheat and burn, increasing the risk of fire.

Advantages of Low Current Photovoltaic Modules

In the face of the various risks and losses of high current photovoltaic modules, low current photovoltaic modules exhibit unique advantages. These advantages are making them increasingly dominant in the market, especially in applications where system reliability and long-term benefits are paramount.

1. Higher Electrical Safety

The low current design of low current photovoltaic modules significantly reduces thermal losses and hot spot risks, enhancing electrical safety. For example, Twisun Pro low current photovoltaic modules use a 10A low current design, lowering operating temperatures and further reducing the likelihood of electrical failures. This design not only extends the module’s lifespan but also ensures reliable operation in various environments.

2. Higher Power Generation Efficiency

Twisun Pro low current photovoltaic modules achieve higher power generation efficiency through a unique three-part cell process. Compared to traditional half-cell processes, the three-part cell process lowers the module’s operating temperature by 20%, increasing power generation by 4.64%. Additionally, the low current design reduces line losses, making each watt of power more effectively converted into usable electricity.

3. System Compatibility and Cost-Effectiveness

The standard size and low current design of low current modules make them more compatible with existing inverters and mounting systems. For example, the Twisun Pro photovoltaic module has a current of around 10A and a standard size of 1.998 square meters, making it suitable for mainstream inverters and mounting brackets. This simplifies the system integration process and reduces installation costs. Additionally, the lightweight dual-glass structure of the low current modules (only 21kg) not only facilitates transportation and installation but also reduces the load on rooftops, further lowering installation difficulty and costs.

4. Performance in Low Irradiance Environments

Low current modules perform exceptionally well in low irradiance environments. Twisun Pro photovoltaic modules start generating power earlier in the morning and stop later in the evening under low light conditions, extending daily power generation time. This feature allows low current modules to maintain high efficiency in various weather conditions, significantly increasing overall power generation.

5. Longer Lifespan and Warranty

The ultra-low degradation rate of Twisun Pro low current photovoltaic modules results in only 1% degradation in the first year and 0.4% annually thereafter, ensuring long-term high-efficiency power generation. Additionally, Twisun Pro offers 30 years of product and power warranty for its dual-glass modules. This long-term assurance makes investing in low current modules more economically viable, reducing maintenance and replacement costs.

Conclusion

In summary, Twisun Pro low current photovoltaic modules, with their significant advantages in electrical safety, power generation efficiency, system compatibility, and cost-effectiveness, have become a wiser choice in the market. They address the various risks associated with high current photovoltaic modules while providing customers with safer, more efficient, and more reliable photovoltaic solutions. Choosing Twisun Pro low current photovoltaic modules will bring higher returns and longer lifespan to your photovoltaic system.

Since 2008, Maysun Solar has been committed to producing high-quality photovoltaic modules. We manufacture a variety of solar panels, such as IBC, HJT, TOPCon solar panels, and balcony solar power stations, all featuring advanced technology, superior performance, and guaranteed quality. Maysun Solar has successfully established offices and warehouses in many countries and forged long-term partnerships with excellent installers! For the latest solar panel quotes or any photovoltaic-related inquiries, please contact us. We are dedicated to serving you, and our products offer a secure guarantee.

Empowering Factories with Solar Energy A Strategic Tool for Controlling Production Electricity Costs

Commercial and industrial solar is becoming a key solution for factories to reduce electricity costs and hedge against price fluctuations. This article systematically analyzes its deployment models, cost advantages, and sustainable value pathways.

How Businesses Can Offset Carbon Taxes with Solar Power

This article analyzes the latest carbon tax policies and photovoltaic deduction strategies, helping European businesses legally reduce taxes, increase profits through solar investment, and achieve a win-win situation for both economy and environment.

Forecast and Response: Seizing the Next Decade’s Growth Dividend in Europe’s Commercial and Industrial Photovoltaics Market

Maysun Solar analyzes the growth trends of commercial and industrial photovoltaics in Europe over the next ten years, from policies and ESG to technological innovation, helping companies seize the initiative in the energy transition.

How to Calculate Solar System ROI and Optimize Long-Term Returns?

Solar power is becoming a key solution for businesses to reduce costs and improve efficiency. Accurately calculating ROI and optimizing long-term returns are essential to maximizing investment value.

Will Agrivoltaics Affect Crop Growth?

Agrivoltaics combines solar energy and agriculture to reduce up to 700 tons of CO₂ per MW, improve water use, and boost crop growth for sustainable farming.

6.5 Billion Loss Hits Photovoltaics: Reshaping or Elimination?

In 2025, the photovoltaic market may see a turnaround as some companies take early action. A €6.5 billion loss is driving businesses to explore new growth areas like energy storage and hydrogen. Which giants will break through? Industry transformation is accelerating!