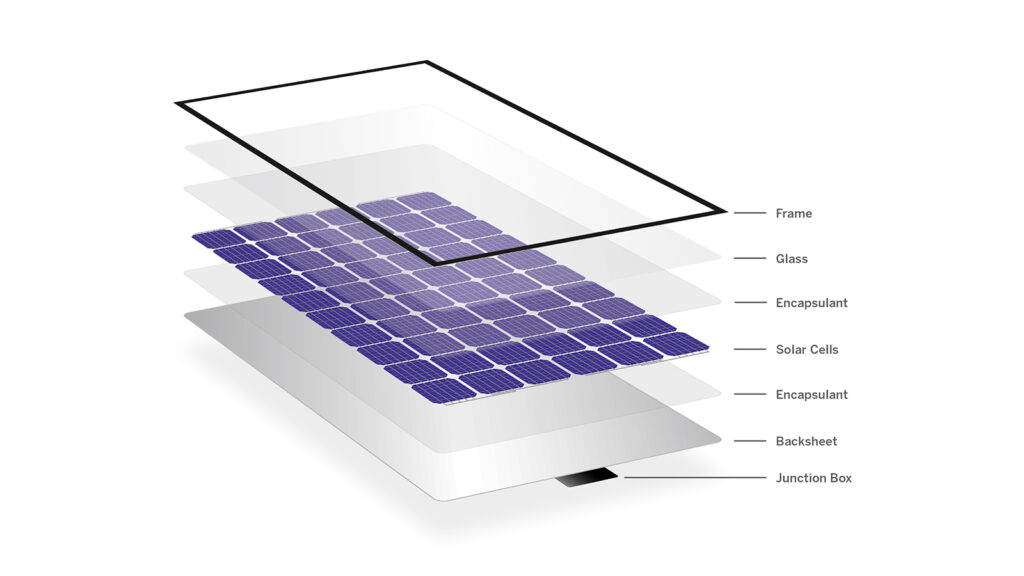

The composition of photovoltaic panels is a technological product consisting of cell, EVA backing, glass panels and other components pressed together. Everyone should pay attention to the protection of PV panels during the process of purchase and transportation and installation, otherwise it will cause the breakage of the glass of PV panels, which will lead to unnecessary loss of cost. Then this article will list some of the reasons that will cause the glass backsheet of photovoltaic panels to break, in order to cause everyone to pay attention to the protection of photovoltaic panels.

Characteristics of photovoltaic glass panels:

Photovoltaic glass has a high solar transmission ratio, low absorption ratio, low reflection ratio and high strength. The quality of photovoltaic glass directly determines the product performance, efficiency and life of photovoltaic modules, so the technical certification of photovoltaic glass is more stringent and complex.

Reasons for glass backsheet cracking:

1. Construction factors

During the operation of photovoltaic, handling photovoltaic modules in the process, the surface of the components accidentally encountered sharp objects.

The construction and installation of the power station construction period is not standardized, bumping components.

When adjusting the installation position of the PV module, the wrong method of knocking the module is used.

2. Environmental factors

Mountain photovoltaic power station due to the complexity of the terrain, the mountain has fallen rocks fall, hitting the component glass.

Part of the land nature is soft, bracket foundation sinking, resulting in bracket deformation, due to bracket through the pressure block and component fixed, the component is subject to stress, the edge frame extrusion caused by glass shattering.

There are sandstorm bad climate places, if the whole bracket foundation is not particularly solid, the components are easy to be lifted up, after falling caused the whole glass shattered.

3. Component factors

Components are made of tempered glass, there is a certain self-destruct rate. In addition, if there are quality defects, such as stones, impurities, bubbles and other defects, especially impurities in the glass, is the weak point of tempered glass, is also a stress concentration, thermal expansion and contraction of the harsh environment, prone to self-explosion; despite this, the industry also has some conventional wisdom, part of the battery component manufacturers to face the objective reality, allowing glass suppliers to provide tempered glass has a certain rate of self-explosion (generally 0.03%).

In addition, if there is a hot spot effect inside the module, resulting in high local temperature, long-term down the module glass will also produce self-explosion.

4. Other factors

Installed in the countryside and rural photovoltaic projects, distributed power plants, etc., there are often children playing and playing in the vicinity, may cause the glass to break.

The danger of broken glass backsheet

After the glass is broken, the safety protection performance of the PV module is reduced, and water vapor, moisture and rainwater can easily enter and cause internal short circuit, which seriously affects the operation safety of the power station.

Maysun Solar produces PV modules with specially toughened glass. The tempering of the glass is to increase the strength of the glass to resist the impact of wind, sand and hail, and to play a role in long-term protection of solar cells. Tempering of panel glass is done by heating the glass to about 700°C in a horizontal tempering furnace and cooling it quickly and evenly using cold air to create uniform compressive stress on the surface and tensile stress on the inside, effectively improving the bending and impact resistance of the glass. After tempering the panel glass, the strength of the glass can be increased by 4 to 5 times compared to ordinary glass.

Maysun, as a professional PV module manufacturer with 15 years of experience, has a wide range of high strength PV panels, welcome to click the button to inquire or browse our products.

You may also like:

Will Agrivoltaics Affect Crop Growth?

Agrivoltaics combines solar energy and agriculture to reduce up to 700 tons of CO₂ per MW, improve water use, and boost crop growth for sustainable farming.

6.5 Billion Loss Hits Photovoltaics: Reshaping or Elimination?

In 2025, the photovoltaic market may see a turnaround as some companies take early action. A €6.5 billion loss is driving businesses to explore new growth areas like energy storage and hydrogen. Which giants will break through? Industry transformation is accelerating!

What’s New in Solar Energy (March 2025)

March’s solar news highlights include rooftop solar meeting two-thirds of global demand, China’s market reforms potentially boosting solar demand and module prices, France revising solar targets in PPE 3, and challenges in Europe with declining capture rates and price volatility.

Zero-Investment Solar Projects: How to Earn Passive Income Through Rooftop Leasing?

Monetize your idle rooftop and earn stable annual rent! With the photovoltaic rooftop leasing model, businesses can generate long-term revenue without investment, reduce operating costs, and achieve a green transition.

How to Optimize Photovoltaic Power Plant Operations with AI and Big Data

This article explores three methods of using AI to enhance power generation revenue and reduce operation and maintenance costs in intelligent photovoltaic operations.

Solar Module Costs May Rise by 10% in 2026! In-Depth Analysis of CBAM’s Impact on the Industry

Table of Contents Introduction to CBAM 1. Why Did the EU Introduce CBAM? As the challenges posed by global climate change intensify, governments worldwide are accelerating their efforts to achieve carbon neutrality. The European Union, a leader in global carbon reduction initiatives, introduced