1. Why Cleaning and Maintenance Are Crucial

As commercial and industrial photovoltaic systems rapidly expand across Europe, post-installation operation and maintenance (O&M) are becoming key factors in determining the internal rate of return (IRR). Especially in the context of high electricity prices and ongoing policy incentives, even a 0.5%–1% drop in energy generation efficiency can significantly impact the overall return structure.

According to studies by the IEA and Fraunhofer ISE, surface contamination of modules, shading, and equipment aging are the three primary causes of power output decline. Real-world data show that PV systems not cleaned regularly experience an average efficiency drop of 3%–15%, and even higher in agricultural or heavy industrial environments.

Therefore, regular cleaning, real-time monitoring, and early warning mechanisms are not just ways to enhance system efficiency—they are essential strategies to extend equipment lifespan and secure financial returns. Maintenance should not be a reactive process, but a standardized part of the system’s lifecycle.

For commercial and industrial users, a photovoltaic system is no longer a one-time investment. It marks the beginning of long-term energy asset management. Cleaning and maintenance are never “optional”—they are necessary conditions to ensure the continuous realization of solar value.

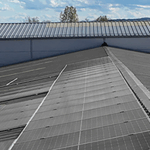

2. Recommendations for Optimizing PV Module Cleaning

The cleanliness of module surfaces is a key factor affecting the power generation efficiency of photovoltaic systems. As previously mentioned, contaminants such as dust, bird droppings, pollen, and industrial particles can lead to energy losses ranging from 3% to 15%. The larger the system, the greater the impact.

1. Cleaning frequency should be adjusted based on specific environmental conditions

The cleaning schedule should be tailored to the surrounding environment: once per quarter in agricultural areas, once per month in industrial zones, and every 2–4 weeks in high-pollution areas. By incorporating data such as rainfall and dust index, cleaning frequencies can be adjusted more scientifically. All inspection results should be documented to support future maintenance optimization.

Recommended cleaning frequencies for typical commercial and industrial scenarios:

Recommended Cleaning Frequency for Typical Commercial and Industrial PV Systems

| Scenario Type | Recommended Cleaning Frequency | Additional Notes |

|---|---|---|

| Urban office rooftops | 1–2 times per year | Recommended cleaning during seasonal transitions to remove dust and pollen |

| Industrial zones and logistics parks | Once per quarter | Prevents dust and industrial residue from affecting light transmission |

| Agricultural facilities (e.g. livestock roofs) | Once per month | Regularly clean bird droppings, organic matter, and moss |

| Coastal or port areas | Once per quarter | Prevent salt fog and corrosion; use purified water when needed |

Note: Frequencies are recommended values and should be dynamically adjusted based on module monitoring data.

2. Cleaning Methods Should Follow the Principle of “Low Damage, High Efficiency”

While high-pressure water guns, corrosive cleaners, or hard brushes can improve cleaning efficiency in the short term, they pose a risk of causing micro-damage to the glass surface, frame seals, and other structures. The following recommended methods should be prioritized:

Use soft-bristled rollers or silicone scrapers, paired with deionized water or purified water

Control the water pressure within 30–40 bar to avoid impact damage

For sloped roofs or high-rise buildings, it is recommended to use telescoping cleaning equipment with fall protection devices or to engage third-party professional services

Avoid using chlorine-based cleaning liquids, alcohol-based solvents, and metal tools for wiping

In large-scale commercial and industrial scenarios, consider deploying automated rail-based cleaning systems or water recycling cleaning vehicles to enhance efficiency and reduce human intervention.

3. Cleaning Should Avoid High-Temperature Operation Periods

Cleaning should be scheduled before sunrise or after power generation ends in the evening to prevent modules from encountering water under high temperatures, which could cause thermal stress and affect structural stability.

While rain can partially remove floating dust, it cannot replace systematic manual cleaning, especially for adhesive pollutants (such as bird droppings and oil stains), which are almost ineffective at being removed by rain.

After cleaning, safety checks should be performed on key areas such as combiner boxes, cable joints, and drainage channels to ensure that the system operates without interference.

3. From Reactive Maintenance to Proactive Monitoring and Early Warning Mechanisms

For commercial and industrial photovoltaic projects, long-term efficient operation is the key factor that truly impacts investment returns.

However, many companies only realize the importance of maintenance when power generation anomalies or revenue declines occur. The reactive approach is no longer sufficient to meet the stability and efficiency requirements of modern photovoltaic systems.

Why Switch to Intelligent Monitoring?

Currently, an increasing number of commercial and industrial photovoltaic projects are introducing remote monitoring platforms and intelligent early warning mechanisms. The core advantages are:

Real-time monitoring of system status: The platform continuously monitors the status of inverters, meters, and each group of modules.

Early fault detection: When anomalies such as abnormal power generation, inverter communication interruptions, or voltage fluctuations occur, the system automatically sends out warnings.

Reduced downtime for energy generation: Shortens troubleshooting time, reduces energy loss, and improves the annual return rate (IRR).

How to Improve Maintenance Efficiency?

Deploy monitoring systems at grid connection: It is recommended to select compatible monitoring systems with inverter or meter manufacturers to avoid system incompatibility issues when retrofitting.

Set basic warning thresholds: For example, if daily power fluctuations exceed ±10%, this can be set as a primary warning.

Schedule regular remote inspections: Operations and maintenance teams or system integrators should generate quarterly operation reports to identify efficiency fluctuation trends.

Outsource professional maintenance teams: Standardize equipment cleaning, testing, and maintenance to avoid the accumulation of risks from a “repair-only” approach.

Intelligent Maintenance Brings Improved Returns

According to feedback from multiple EPC and O&M teams, after introducing remote monitoring and early warning systems, the average fault response time for photovoltaic projects was shortened by 40%-60%, and system energy generation efficiency improved by approximately 3%-5%. At current electricity prices, this difference is significant enough to notably impact the company’s annual electricity savings.

Comparison Between Traditional O&M and Intelligent Monitoring

| Dimension | Traditional O&M | Intelligent Monitoring O&M |

|---|---|---|

| Monitoring Method | Manual inspection, periodic meter reading | Remote platform real-time monitoring, automatic data upload |

| Fault Response | Relies on manual judgment, delayed response | Immediate alert for anomalies, quick fault location |

| Maintenance Cycle | Periodic fixed maintenance, difficult to personalize | Dynamically scheduled based on actual operating conditions |

| Impact on ROI | Unpredictable power generation loss, unstable returns | Improves power generation stability, increases IRR by 2-5% |

4. Long-Term Benefits of Effective Maintenance

Photovoltaic systems are not one-time asset installations but require continuous management as energy facilities. Proper operation and maintenance (O&M) not only reduce system risks but also directly determine the overall return structure throughout their lifecycle. Real-world data shows:

Power generation efficiency can increase by 5–15%, especially in environments with high pollution or dust accumulation, where the improvement is more significant.

The rate of equipment aging is reduced, extending system lifespan by 3–5 years and reducing unexpected maintenance and operational downtime costs.

O&M records and operational data help companies build credible advantages in green audits, ESG ratings, and financing assessments.

In the context of high electricity prices and growing green compliance pressures, standardized O&M has become a necessary condition for ensuring the long-term value realization of photovoltaic assets, rather than an optional choice.

Since 2008, Maysun Solar has been dedicated to producing high-quality photovoltaic modules. Our range of solar panels, including IBC, HJT and TOPCon panels, and balcony solar stations, are manufactured using advanced technology and offer excellent performance and guaranteed quality. Maysun Solar has successfully established offices and warehouses in many countries and built long-term partnerships with top installers! For the latest quotes on solar panels or any photovoltaic-related inquiries, please contact us. We are committed to serving you, and our products provide reliable assurance.

References:

Fraunhofer Institute for Solar Energy Systems ISE. Photovoltaics Report. March 2024.

https://www.ise.fraunhofer.de/en/publications/studies/photovoltaics-report.html

International Energy Agency (IEA). Renewables 2023: Analysis and Forecast to 2028. December 2023.

https://www.iea.org/reports/renewables-2023

SolarPower Europe. O&M Best Practices Guidelines – 3rd Edition. 2022.

https://www.solarpowereurope.org/insights/operations-and-maintenance-best-practices-guidelines

PV Tech. How Soiling Impacts Solar Output and How to Prevent It. 2023.

https://www.pv-tech.org/technical-papers/how-soiling-impacts-solar-output-and-how-to-prevent-it

You may also like:

How to Effectively Clean and Intelligently Maintain Photovoltaic Systems for Optimal Performance?

Explore how scientific cleaning and intelligent maintenance can ensure the efficient operation of commercial and industrial photovoltaic systems. Practical advice covers module cleaning frequency, monitoring system configuration, and long-term strategies for energy savings and performance enhancement.

2025 European Photovoltaic Policy Map: Deployment Paths and Regional Strategies for Commercial and Industrial Photovoltaics

A comprehensive analysis of the 2025 European commercial and industrial photovoltaic policy map, focusing on deployment strategies, incentive comparisons, and zero-investment models to support businesses in achieving an efficient and green transition.

Empowering Factories with Solar Energy A Strategic Tool for Controlling Production Electricity Costs

Commercial and industrial solar is becoming a key solution for factories to reduce electricity costs and hedge against price fluctuations. This article systematically analyzes its deployment models, cost advantages, and sustainable value pathways.

How Businesses Can Offset Carbon Taxes with Solar Power

This article analyzes the latest carbon tax policies and photovoltaic deduction strategies, helping European businesses legally reduce taxes, increase profits through solar investment, and achieve a win-win situation for both economy and environment.

Forecast and Response: Seizing the Next Decade’s Growth Dividend in Europe’s Commercial and Industrial Photovoltaics Market

Maysun Solar analyzes the growth trends of commercial and industrial photovoltaics in Europe over the next ten years, from policies and ESG to technological innovation, helping companies seize the initiative in the energy transition.

How to Calculate Solar System ROI and Optimize Long-Term Returns?

Solar power is becoming a key solution for businesses to reduce costs and improve efficiency. Accurately calculating ROI and optimizing long-term returns are essential to maximizing investment value.