What is a Solar Panel encapsulation? What does it do?

Solar Panel Encapsulation mainly include EVA, POE, PVB (polyvinyl butyral) encapsulation film.

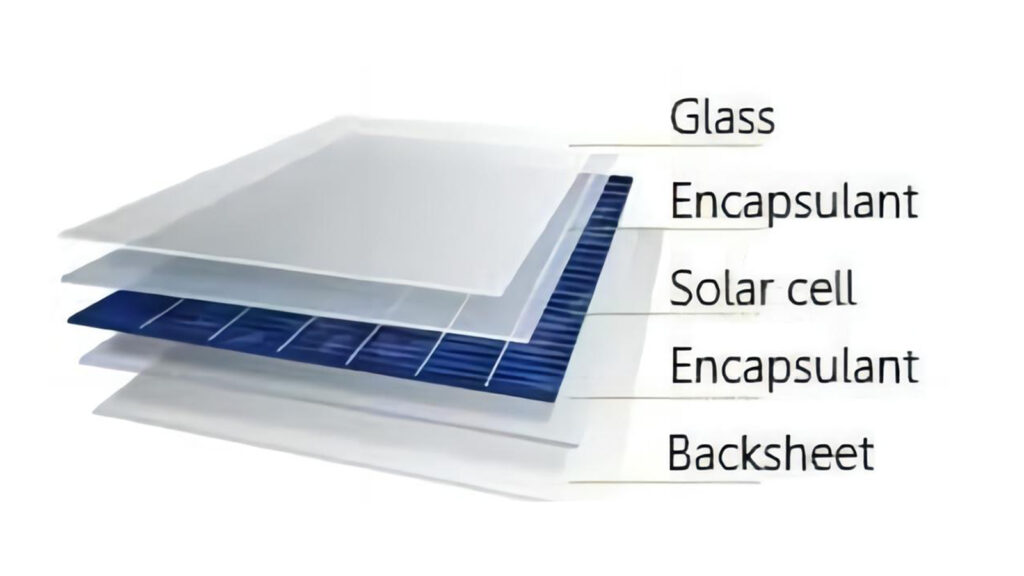

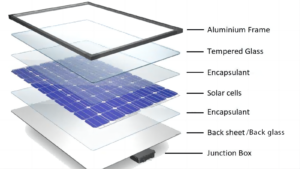

Solar Panel encapsulation adhesive film is placed between the glass of the Solar Panel module and the solar cell or the back sheet and the solar cell to encapsulate and protect the solar cell, and is one of the key materials of the Solar Panel module.

How many kinds of Solar Panel encapsulation films?

EVA: EVA resin is used as the main raw material, modified by adding cross-linking agent, silane coupling agent, light stabilizer, antioxidant, ultraviolet absorber and other additives, and formed by melt processing.

It has excellent light transmittance and wide process window, and because EVA resin and additives are polar materials, it has good compatibility and absorption effect.

POE: POE resin is used as the main raw material, modified by adding crosslinking agent, silane coupling agent, light stabilizer, antioxidant, ultraviolet absorber and other additives, and formed by melt processing.

It has excellent water vapor barrier and anti-PID performance, but because POE is a non-polar resin, it is easy to cause additive precipitation.

PVB: PVB resin is used as the main raw material, modified by adding plasticizers, silane coupling agents, light stabilizers, antioxidants, ultraviolet absorbers and other additives, and formed by melt processing. Has excellent mechanical strength.

EPE: EVA and POE co-extrusion melt-processed film.

Transparent film: including high-transparency type and UV cut-off type. The high-transparency type can pass through the full-band sunlight to maximize the conversion efficiency of solar energy. The UV cut-off type has the ability to absorb ultraviolet rays, which can effectively improve the aging of materials caused by ultraviolet rays.

White film: including non-woven composite structure and pre-crosslinked white film, mainly colored by titanium dioxide. The non-woven composite structure white film has good cushioning effect, anti-spill glue effect, and zero depth reflection improves power gain.

The pre-crosslinked white film can control the whitening, wrinkling and good reflectivity of overflowing glue by adjusting the initial degree of crosslinking.

Single-layer structure adhesive film: refers to pure EVA, POE, PVB adhesive film.

Multi-layer composite structure adhesive film: refers to the white film and EPE co-extruded adhesive film made of EVA, POE and non-woven fabric.

Frosted film: the front and back sides are frosted film with irregular patterns, anti-sticking and non-slip.

Prism-shaped film: The surface of the steel roller is a film with regular prismatic patterns, which is anti-sticking and non-slip, and is suitable for high-weight film.

Casting film: The film is processed and formed by casting. At present, the Solar Panel encapsulation film is mainly processed and formed by casting. The cast film has good softness, high fluidity, small internal stress and low shrinkage.

Calendered film: a film formed by calendering. The calendered film has high mechanical strength, high hardness, large internal stress and good flatness.

Thermosetting adhesive film: Under a certain temperature and time, a network structure is formed through a chemical cross-linking reaction to produce an adhesive film with mechanical strength and bonding and sealing effect. EVA is a thermosetting film, and POE has two types: thermosetting and thermoplastic. The thermosetting adhesive film is mainly suitable for the encapsulation of conventional crystalline silicon Solar Panel modules.

Thermoplastic film: A non-chemically cross-linked, hot-melt film without added peroxides. It has the characteristics of recyclable utilization and repeated processing. PVB is a thermoplastic film, mainly suitable for BIPV (Building Integrated Solar Panel) Solar Panel modules. Thermoplastic POE is mainly suitable for thin film Solar Panel modules.

For which different types of PV modules are different Encapsulation suitable?

Ordinary crystalline silicon modules often use EVA film as the main encapsulation. The front of single-glass modules uses high-transmittance EVA film, and the back panel uses UV-cut EVA film.

Both the front and back of the double-glass module use high-transparency POE film. Thin-film modules commonly use PVB film, UV cut-off POE film and thermoplastic POE film as the main encapsulations. Maysun’s double glass products are applied with POE film, you can click on the product for more details.

Why is Solar Panel encapsulation important?

Solar Panel encapsulation adhesive film, as the core material of Solar Panel modules, is very important to the encapsulation process and performance of modules.

The working environment of Solar Panel modules is mainly outdoors, exposed to sunlight, rain, ice and snow for a long time, and the warranty period of Solar Panel modules usually requires more than 25 years.

Therefore, encapsulations are constantly improving technology in terms of characteristics and material matching, process adaptation, performance requirements, and reliability assurance.

How does the Solar Panel encapsulation ensure the excellent operation of the Solar Panel?

Keeps the ability to pass light and electricity by keeping wetness out: Moisture and dust that accumulate on solar cells can block sunlight and disrupt the flow of electricity. Encapsulation prevents moisture and dust from causing damage by providing a protective cover.

Keeps the Solar Panel‘s structure in good shape: Encapsulation helps protect the Solar Panel from deformation and maintains its integrity. It prevents damage and degradation of the delicate solar cells over time.

To keep Solar Panels working: Ensuring proper encapsulation is crucial for the performance and lifespan of a Solar Panel. It serves as a protective layer for the sensitive solar cells and electrical components, helping them maintain optimal performance.

Ensure the reliability of Solar Panels: The warranty of modules for more than 25 years has strict requirements on performance degradation and material aging.

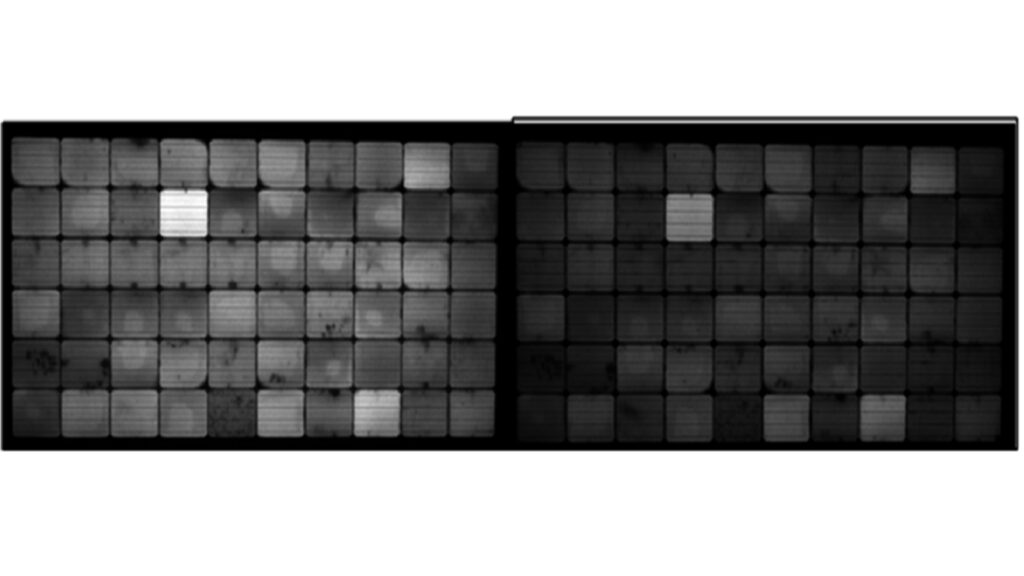

The PID effect causes the power attenuation of the module, and the entry of water vapor easily causes the hydrolysis reaction of the EVA film to generate acetic acid, which reacts with the alkali precipitated on the glass surface to produce a large number of freely mobile Na ions, which move to the surface of the cell under the action of an external electric field. And enriched to the anti-reflection layer to produce PID effect.

Note: What is the PID effect?

PID effect: Water vapor and high temperature will cause the volume resistivity of the adhesive film to decrease and accelerate the corrosion of the battery ribbon, which will further lead to PID attenuation and component aging.

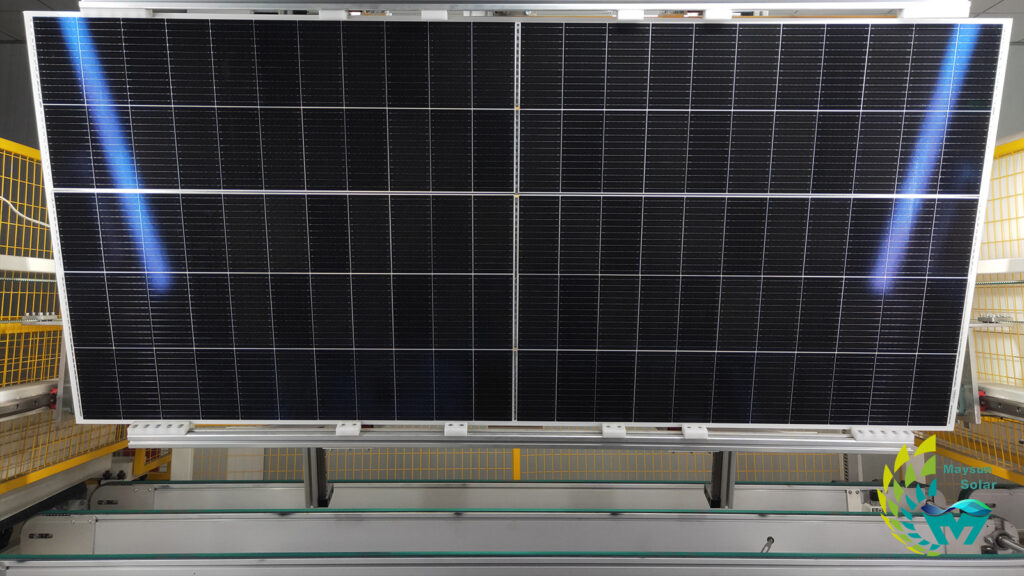

IEC/TC82 (International Electrotechnical Commission Solar Solar Panel Energy System Standardization Technical Committee) also developed and released a series of standards IEC62788 “Material Test Procedures for Solar Panel Modules encapsulations”.Since 2008, Maysun Solar Panels has been focusing on the production of high-quality Solar Panel modules that have already reached international standard encapsulations.

Maysun solar has a wide range of shingled, half cut and black frame, all black, silver frame Solar Panels to choose from, they offer great performance and stylish designs that will complement any building fusion. Maysun Solar have a wide range established offices, warehouses in many countries, and established long-term cooperative relationships with excellent installers! Please feel free to contact us for the latest module quotes or any Solar Panel related inquiries.

New Photovoltaic news you should know about (March 2024)

Table of Contents REC Unveils a 430 W Heterojunction Solar Module Boasting 22.2% Efficiency REC, a Singapore-based PV module manufacturer, introduces its residential solar modules featuring Alpha heterojunction cell technology. Production has commenced at REC’s Industry 4.0 fab in Singapore, with initial shipments

IBC Solar Modules vs. Bifacial Glass-Glass Solar Modules: Which Is More Suitable for Winter or Low-Light Conditions?

Table of Contents Introduction As the demand for renewable energy continues to surge, advancements in solar technology have broadened the spectrum of component choices available to us. Among these, IBC (Interdigitated Back Contact) full black solar modules have garnered special attention due to

Why Are Lightweight Bifacial Solar Panels the Best Choice for Balcony Solar Power Plants?

Table of Contents In the quest for efficient and eco-friendly home energy solutions, solar photovoltaic technology has emerged as a key player due to its sustainability and clean energy benefits. Particularly in the space-constrained urban settings, the effective conversion of every inch of

Questions You Might Ask About Balcony Solar Power Plants in 2024

Table of Contents What is a Balcony Solar Power Plant? Similar to a traditional photovoltaic panel, a Balcony Solar Power Plant is a device designed to generate electricity from solar energy. This green energy generator is specifically tailored for self-consumption, but it comes with

A Step-by-Step DTU Guide for Balcony Solar Power Plants

As renewable energy becomes increasingly integral in our daily lives, Maysun Solar’s Balcony Solar Power Station, with its advanced technology and user-friendly design, represents a transformative approach to home solar solutions. The integration of a Data Transfer Unit (DTU) enhances its smart functionality

What Are The Main Components of Solar Panels?

What are the main components of solar panel? Solar panels, the cornerstone of solar energy technology, are composed of several integral parts, each contributing to their ability to harness sunlight and convert it into electrical energy. In this article, we will explore the essential